Product Description

You can kindly find the specification details below:

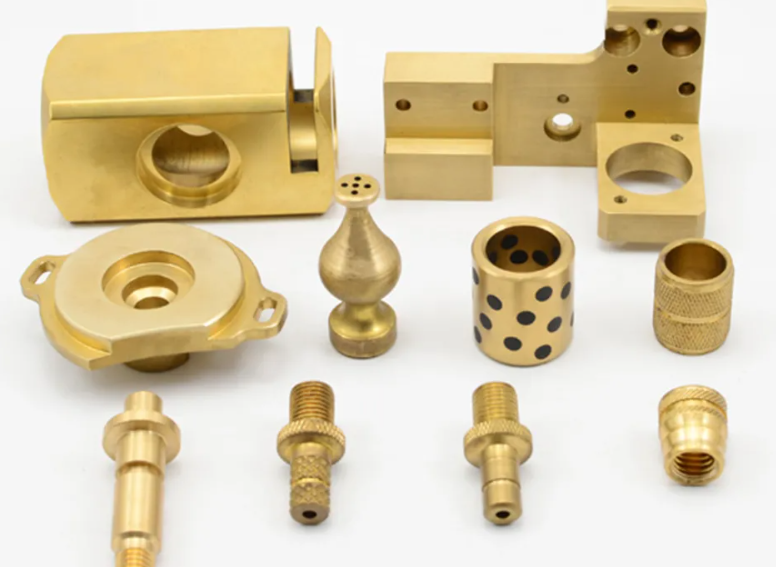

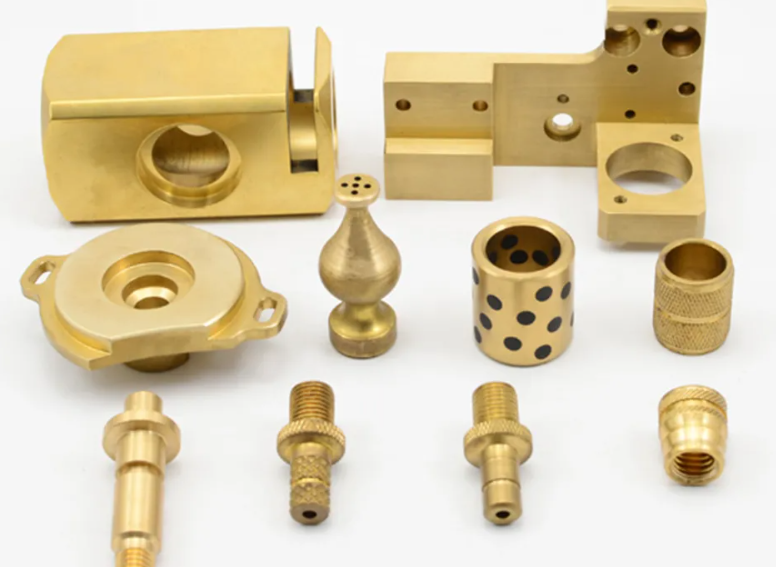

HangZhou Mastery Machinery Technology Co., LTD helps manufacturers and brands fulfill their machinery parts by precision manufacturing. High precision machinery products like the shaft, worm screw, bushing, couplings, joints……Our products are used widely in electronic motors, the main shaft of the engine, the transmission shaft in the gearbox, couplers, printers, pumps, drones, and so on. They cater to different industries, including automotive, industrial, power tools, garden tools, healthcare, smart home, etc.

Mastery caters to the industrial industry by offering high-level Cardan shafts, pump shafts, and a bushing that come in different sizes ranging from diameter 3mm-50mm. Our products are specifically formulated for transmissions, robots, gearboxes, industrial fans, and drones, etc.

Mastery factory currently has more than 100 main production equipment such as CNC lathe, CNC machining center, CAM Automatic Lathe, grinding machine, hobbing machine, etc. The production capacity can be up to 5-micron mechanical tolerance accuracy, automatic wiring machine processing range covering 3mm-50mm diameter bar.

Key Specifications:

| Name | Shaft/Motor Shaft/Drive Shaft/Gear Shaft/Pump Shaft/Worm Screw/Worm Gear/Bushing/Ring/Joint/Pin |

| Material | 40Cr/35C/GB45/70Cr/40CrMo |

| Process | Machining/Lathing/Milling/Drilling/Grinding/Polishing |

| Size | 2-400mm(Customized) |

| Diameter | φ12(Customized) |

| Diameter Tolerance | 0.008mm |

| Roundness | 0.01mm |

| Roughness | Ra0.4 |

| Straightness | 0.01mm |

| Hardness | Customized |

| Length | 32mm(Customized) |

| Heat Treatment | Customized |

| Surface treatment | Coating/Ni plating/Zn plating/QPQ/Carbonization/Quenching/Black Treatment/Steaming Treatment/Nitrocarburizing/Carbonitriding |

Quality Management:

- Raw Material Quality Control: Chemical Composition Analysis, Mechanical Performance Test, ROHS, and Mechanical Dimension Check

- Production Process Quality Control: Full-size inspection for the 1st part, Critical size process inspection, SPC process monitoring

- Lab ability: CMM, OGP, XRF, Roughness meter, Profiler, Automatic optical inspector

- Quality system: ISO9001, IATF 16949, ISO14001

- Eco-Friendly: ROHS, Reach.

Packaging and Shipping:

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business.

Mastery utilizes several different shipping methods that are detailed below:

For Samples/Small Q’ty: By Express Services or Air Fright.

For Formal Order: By Sea or by air according to your requirement.

Mastery Services:

- One-Stop solution from idea to product/ODM&OEM acceptable

- Individual research and sourcing/purchasing tasks

- Individual supplier management/development, on-site quality check projects

- Muti-varieties/small batch/customization/trial orders are acceptable

- Flexibility on quantity/Quick samples

- Forecast and raw material preparation in advance are negotiable

- Quick quotes and quick responses

General Parameters:

If you are looking for a reliable machinery product partner, you can rely on Mastery. Work with us and let us help you grow your business using our customizable and affordable products. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

How do drivelines ensure optimal power transfer while minimizing energy losses?

Drivelines play a crucial role in ensuring optimal power transfer from the engine to the wheels while minimizing energy losses. The design and components of the driveline system are carefully engineered to maximize efficiency and minimize power wastage. Here are some key factors that contribute to achieving optimal power transfer and minimizing energy losses within a driveline:

1. Efficient Power Transmission:

Drivelines utilize various components, such as transmissions, clutches, and torque converters, to transmit power from the engine to the wheels. These components are designed to minimize energy losses by reducing friction, improving gear mesh efficiency, and optimizing torque transfer. For example, using low-friction materials, such as roller bearings, and employing advanced gear designs, like helical or hypoid gears, can help reduce power losses due to friction and gear meshing.

2. Gear Ratio Optimization:

The selection of appropriate gear ratios is essential for achieving optimal power transfer. By choosing gear ratios that match the engine’s power characteristics and the vehicle’s driving conditions, the driveline can efficiently convert and transmit power to the wheels. Optimized gear ratios ensure that the engine operates within its optimal RPM range, reducing unnecessary power losses and improving overall efficiency.

3. Limited Slip Differentials:

In driveline systems with multiple driven wheels (such as all-wheel drive or four-wheel drive), limited slip differentials (LSDs) are often employed to distribute power between the wheels. LSDs allow for better traction by transferring torque to the wheels with more grip while minimizing energy losses. By allowing some degree of differential wheel speed, LSDs ensure power is efficiently transmitted to the wheels that can utilize it most effectively.

4. Hybrid and Electric Drivetrains:

In hybrid and electric drivetrains, driveline systems are designed to optimize power transfer and minimize energy losses specific to the characteristics of electric motors and energy storage systems. These drivetrains often utilize sophisticated power electronics, regenerative braking systems, and advanced control algorithms to efficiently manage power flow and energy regeneration, resulting in improved overall system efficiency.

5. Aerodynamic Considerations:

Drivelines can also contribute to optimal power transfer by considering aerodynamic factors. By minimizing air resistance through streamlined vehicle designs, efficient cooling systems, and appropriate underbody airflow management, drivelines help reduce the power required to overcome aerodynamic drag. This, in turn, improves overall driveline efficiency and minimizes energy losses.

6. Advanced Control Systems:

The integration of advanced control systems within drivelines allows for optimized power transfer and efficient operation. Electronic control units (ECUs) monitor various parameters such as throttle position, vehicle speed, and driving conditions to adjust power distribution, manage gear shifts, and optimize torque delivery. By continuously adapting to real-time conditions, these control systems help maximize power transfer efficiency and minimize energy losses.

7. Material Selection and Weight Reduction:

The choice of materials and weight reduction strategies in driveline components contribute to minimizing energy losses. Lightweight materials, such as aluminum or composites, reduce the overall weight of the driveline system, resulting in reduced inertia and lower power requirements. Additionally, reducing the weight of rotating components, such as driveshafts or flywheels, helps improve driveline efficiency by minimizing energy losses associated with rotational inertia.

8. Regular Maintenance and Lubrication:

Proper maintenance and lubrication of driveline components are essential for minimizing energy losses. Regular maintenance ensures that driveline components, such as bearings and gears, are in optimal condition, minimizing frictional losses. Additionally, using high-quality lubricants and maintaining appropriate lubrication levels reduces friction and wear, improving driveline efficiency.

By incorporating these design considerations and engineering techniques, drivelines can achieve optimal power transfer while minimizing energy losses. This leads to improved overall efficiency, enhanced fuel economy, and reduced environmental impact.

Can driveline components be customized for specific vehicle or equipment requirements?

Yes, driveline components can be customized to meet specific vehicle or equipment requirements. Manufacturers and suppliers offer a range of options for customization to ensure optimal performance, compatibility, and integration with different vehicles or equipment. Customization allows for tailoring the driveline components to specific powertrain configurations, operating conditions, torque requirements, and space constraints. Let’s explore the details of customization for driveline components:

1. Powertrain Configuration:

Driveline components can be customized to accommodate different powertrain configurations. Whether it’s a front-wheel drive, rear-wheel drive, or all-wheel drive system, manufacturers can design and provide specific components such as differentials, gearboxes, and drive shafts that are compatible with the required power distribution and torque transfer characteristics of the particular configuration.

2. Torque Capacity:

Driveline components can be customized to handle specific torque requirements. Different vehicles or equipment may have varying torque outputs based on their intended applications. Manufacturers can engineer and produce driveline components with varying torque-handling capabilities to ensure reliable and efficient power transmission for a range of applications, from passenger vehicles to heavy-duty trucks or machinery.

3. Size and Configuration:

Driveline components can be customized in terms of size, shape, and configuration to fit within the space constraints of different vehicles or equipment. Manufacturers understand that each application may have unique packaging limitations, such as limited available space or specific mounting requirements. Through customization, driveline components can be designed and manufactured to align with these specific dimensional and packaging constraints.

4. Material Selection:

The choice of materials for driveline components can be customized based on the required strength, weight, and durability characteristics. Different vehicles or equipment may demand specific material properties to optimize performance, such as lightweight materials for improved fuel efficiency or high-strength alloys for heavy-duty applications. Manufacturers can provide customized driveline components with materials selected to meet the specific performance and operational requirements.

5. Performance Optimization:

Driveline components can be customized to optimize performance in specific applications. Manufacturers can modify aspects such as gear ratios, differential configurations, or clutch characteristics to enhance acceleration, traction, efficiency, or specific performance attributes based on the intended use of the vehicle or equipment. This customization ensures that the driveline components are tailored to deliver the desired performance characteristics for the specific application.

6. Specialized Applications:

For specialized applications, such as off-road vehicles, racing cars, or industrial machinery, driveline components can be further customized to meet the unique demands of those environments. Manufacturers can develop specialized driveline components with features like enhanced cooling, reinforced construction, or increased torque capacity to withstand extreme conditions or heavy workloads.

Overall, customization of driveline components allows manufacturers to meet the specific requirements of different vehicles or equipment. From powertrain configuration to torque capacity, size and configuration, material selection, performance optimization, and specialized applications, customization ensures that driveline components are precisely designed and engineered to achieve the desired performance, compatibility, and integration with specific vehicles or equipment.

Which industries and vehicles commonly use drivelines for power distribution?

Drivelines are widely used in various industries and vehicles for power distribution. They play a crucial role in transmitting power from the engine or power source to the driven components, enabling motion and torque transfer. Here’s a detailed explanation of the industries and vehicles that commonly utilize drivelines for power distribution:

1. Automotive Industry: The automotive industry extensively utilizes drivelines in passenger cars, commercial vehicles, and off-road vehicles. Drivelines are a fundamental component of vehicles, enabling power transmission from the engine to the wheels. They are found in a range of vehicle types, including sedans, SUVs, pickup trucks, vans, buses, and heavy-duty trucks. Drivelines in the automotive industry are designed to provide efficient power distribution, enhance vehicle performance, and ensure smooth acceleration and maneuverability.

2. Agricultural Industry: Drivelines are essential in the agricultural industry for various farming machinery and equipment. Tractors, combines, harvesters, and other agricultural machinery rely on drivelines to transfer power from the engine to the wheels or tracks. Drivelines in agricultural equipment often incorporate power take-off (PTO) units, allowing the connection of implements such as plows, seeders, and balers. These drivelines are designed to handle high torque loads, provide traction in challenging field conditions, and facilitate efficient farming operations.

3. Construction and Mining Industries: Drivelines are extensively used in construction and mining equipment, where they enable power distribution and mobility in heavy-duty machinery. Excavators, bulldozers, wheel loaders, dump trucks, and other construction and mining vehicles rely on drivelines to transfer power from the engine to the wheels or tracks. Drivelines in these industries are designed to withstand rigorous operating conditions, deliver high torque and traction, and provide the necessary power for excavation, hauling, and material handling tasks.

4. Industrial Equipment: Various industrial equipment and machinery utilize drivelines for power distribution. This includes material handling equipment such as forklifts and cranes, industrial trucks, conveyor systems, and industrial vehicles used in warehouses, factories, and distribution centers. Drivelines in industrial equipment are designed to provide efficient power transmission, precise control, and maneuverability in confined spaces, enabling smooth and reliable operation in industrial settings.

5. Off-Road and Recreational Vehicles: Drivelines are commonly employed in off-road and recreational vehicles, including all-terrain vehicles (ATVs), side-by-side vehicles (UTVs), dirt bikes, snowmobiles, and recreational boats. These vehicles require drivelines to transfer power from the engine to the wheels, tracks, or propellers, enabling off-road capability, traction, and water propulsion. Drivelines in off-road and recreational vehicles are designed for durability, performance, and enhanced control in challenging terrains and recreational environments.

6. Railway Industry: Drivelines are utilized in railway locomotives and trains for power distribution and propulsion. They are responsible for transmitting power from the locomotive’s engine to the wheels or driving systems, enabling the movement of trains on tracks. Drivelines in the railway industry are designed to handle high torque requirements, ensure efficient power transfer, and facilitate safe and reliable train operation.

7. Marine Industry: Drivelines are integral components in marine vessels, including boats, yachts, ships, and other watercraft. Marine drivelines are used for power transmission from the engine to the propellers or water jets, providing thrust and propulsion. They are designed to withstand the corrosive marine environment, handle high torque loads, and ensure efficient power transfer for marine propulsion.

These are some of the industries and vehicles that commonly rely on drivelines for power distribution. Drivelines are versatile components that enable efficient power transmission, mobility, and performance across a wide range of applications, contributing to the functionality and productivity of various industries and vehicles.

editor by CX 2024-04-09

China factory Machinery Parts Rotor Gear Shaft Customized Machining Knurling High Precision with Factory Price for Auto Drive Factory Price Drive Line

Product Description

You can kindly find the specification details below:

HangZhou Mastery Machinery Technology Co., LTD helps manufacturers and brands fulfill their machinery parts by precision manufacturing. High precision machinery products like the shaft, worm screw, bushing, couplings, joints……Our products are used widely in electronic motors, the main shaft of the engine, the transmission shaft in the gearbox, couplers, printers, pumps, drones, and so on. They cater to different industries, including automotive, industrial, power tools, garden tools, healthcare, smart home, etc.

Mastery caters to the industrial industry by offering high-level Cardan shafts, pump shafts, and a bushing that come in different sizes ranging from diameter 3mm-50mm. Our products are specifically formulated for transmissions, robots, gearboxes, industrial fans, and drones, etc.

Mastery factory currently has more than 100 main production equipment such as CNC lathe, CNC machining center, CAM Automatic Lathe, grinding machine, hobbing machine, etc. The production capacity can be up to 5-micron mechanical tolerance accuracy, automatic wiring machine processing range covering 3mm-50mm diameter bar.

Key Specifications:

| Name | Shaft/Motor Shaft/Drive Shaft/Gear Shaft/Pump Shaft/Worm Screw/Worm Gear/Bushing/Ring/Joint/Pin |

| Material | 40Cr/35C/GB45/70Cr/40CrMo |

| Process | Machining/Lathing/Milling/Drilling/Grinding/Polishing |

| Size | 2-400mm(Customized) |

| Diameter | φ12(Customized) |

| Diameter Tolerance | 0.008mm |

| Roundness | 0.01mm |

| Roughness | Ra0.4 |

| Straightness | 0.01mm |

| Hardness | Customized |

| Length | 32mm(Customized) |

| Heat Treatment | Customized |

| Surface treatment | Coating/Ni plating/Zn plating/QPQ/Carbonization/Quenching/Black Treatment/Steaming Treatment/Nitrocarburizing/Carbonitriding |

Quality Management:

- Raw Material Quality Control: Chemical Composition Analysis, Mechanical Performance Test, ROHS, and Mechanical Dimension Check

- Production Process Quality Control: Full-size inspection for the 1st part, Critical size process inspection, SPC process monitoring

- Lab ability: CMM, OGP, XRF, Roughness meter, Profiler, Automatic optical inspector

- Quality system: ISO9001, IATF 16949, ISO14001

- Eco-Friendly: ROHS, Reach.

Packaging and Shipping:

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business.

Mastery utilizes several different shipping methods that are detailed below:

For Samples/Small Q’ty: By Express Services or Air Fright.

For Formal Order: By Sea or by air according to your requirement.

Mastery Services:

- One-Stop solution from idea to product/ODM&OEM acceptable

- Individual research and sourcing/purchasing tasks

- Individual supplier management/development, on-site quality check projects

- Muti-varieties/small batch/customization/trial orders are acceptable

- Flexibility on quantity/Quick samples

- Forecast and raw material preparation in advance are negotiable

- Quick quotes and quick responses

General Parameters:

If you are looking for a reliable machinery product partner, you can rely on Mastery. Work with us and let us help you grow your business using our customizable and affordable products. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the compatibility of driveline components with different vehicles?

Manufacturers employ various measures to ensure the compatibility of driveline components with different vehicles. These measures involve careful design, engineering, testing, and standardization processes to meet the specific requirements of each vehicle type. Let’s explore how manufacturers ensure compatibility:

1. Vehicle-Specific Design:

Manufacturers design driveline components with specific vehicle types in mind. Each vehicle type, such as passenger cars, trucks, SUVs, or commercial vehicles, has unique requirements in terms of power output, torque capacity, weight distribution, space constraints, and intended usage. Manufacturers consider these factors during the component design phase to ensure that the driveline components are optimized for compatibility with the intended vehicle type.

2. Engineering and Simulation:

Manufacturers employ advanced engineering techniques and simulation tools to evaluate the performance and compatibility of driveline components. They use computer-aided design (CAD) software and finite element analysis (FEA) simulations to model and analyze the behavior of the components under various operating conditions. This allows them to identify any potential compatibility issues, such as excessive stress, misalignment, or interference, and make necessary design adjustments before moving to the production stage.

3. Prototyping and Testing:

Manufacturers create prototypes of driveline components and subject them to rigorous testing to ensure compatibility. These tests include bench testing, dynamometer testing, and vehicle-level testing. By simulating real-world operating conditions, manufacturers can evaluate the performance, durability, and compatibility of the components. They assess factors such as power transmission efficiency, torque capacity, heat dissipation, noise and vibration levels, and overall drivability to ensure that the components meet the requirements and are compatible with the intended vehicle.

4. Standardization:

Manufacturers adhere to industry standards and specifications to ensure compatibility and interchangeability of driveline components. These standards cover various aspects such as dimensions, material properties, spline profiles, shaft diameters, and mounting interfaces. By following established standards, manufacturers can ensure that their driveline components can be seamlessly integrated into different vehicles from various manufacturers, promoting compatibility and ease of replacement or upgrade.

5. Collaborative Development:

Manufacturers often collaborate closely with vehicle manufacturers during the development process to ensure compatibility. This collaboration involves sharing specifications, design requirements, and performance targets. By working together, driveline manufacturers can align their component designs with the vehicle manufacturer’s specifications, ensuring that the driveline components fit within the vehicle’s space constraints, mating interfaces, and intended usage. This collaborative approach helps optimize compatibility and integration between the driveline components and the vehicle’s overall system.

6. Continuous Improvement:

Manufacturers continuously improve their driveline components based on feedback, field data, and advancements in technology. They gather information from vehicle manufacturers, end-users, and warranty claims to identify any compatibility issues or performance shortcomings. This feedback loop helps drive refinements and enhancements in the design, manufacturing processes, and material selection of the driveline components, ensuring better compatibility and performance in future iterations.

Overall, manufacturers employ a combination of vehicle-specific design, engineering and simulation, prototyping and testing, standardization, collaborative development, and continuous improvement to ensure the compatibility of driveline components with different vehicles. These efforts help optimize power transmission, reliability, and performance, while ensuring a seamless integration of the driveline components into the diverse range of vehicles present in the market.

How do drivelines handle variations in speed and direction during operation?

Drivelines are designed to handle variations in speed and direction during operation, enabling the efficient transfer of power from the engine to the wheels. They employ various components and mechanisms to accommodate these variations and ensure smooth and reliable power transmission. Let’s explore how drivelines handle speed and direction variations:

1. Transmissions:

Transmissions play a crucial role in managing speed variations in drivelines. They allow for the selection of different gear ratios to match the engine’s torque and speed with the desired vehicle speed. By shifting gears, the transmission adjusts the rotational speed and torque delivered to the driveline, enabling the vehicle to operate effectively at various speeds. Transmissions can be manual, automatic, or continuously variable, each with its own mechanism for achieving speed variation control.

2. Clutches:

Clutches are used in drivelines to engage or disengage power transmission between the engine and the driveline components. They allow for smooth engagement during startup and shifting gears, as well as for disconnecting the driveline when the vehicle is stationary or the engine is idling. Clutches facilitate the control of speed variations by providing a means to temporarily interrupt power flow and smoothly transfer torque between rotating components.

3. Differential:

The differential is a key component in drivelines, particularly in vehicles with multiple driven wheels. It allows the wheels to rotate at different speeds while maintaining power transfer. When a vehicle turns, the inside and outside wheels travel different distances and need to rotate at different speeds. The differential allows for this speed variation by distributing torque between the wheels, ensuring smooth operation and preventing tire scrubbing or driveline binding.

4. Universal Joints and CV Joints:

Universal joints and constant velocity (CV) joints are used in drivelines to accommodate variations in direction. Universal joints are typically employed in drivelines with a driveshaft, allowing for the transmission of rotational motion even when there is an angular misalignment between the driving and driven components. CV joints, on the other hand, are used in drivelines that require constant velocity and smooth power transfer at varying angles, such as front-wheel drive vehicles. These joints allow for a consistent transfer of torque while accommodating changes in direction.

5. Transfer Cases:

In drivelines with multiple axles or drivetrains, transfer cases are used to distribute power and torque to different wheels or axles. Transfer cases are commonly found in four-wheel drive or all-wheel drive systems. They allow for variations in speed and direction by proportionally distributing torque between the front and rear wheels, or between different axles, based on the traction requirements of the vehicle.

6. Electronic Control Systems:

Modern drivelines often incorporate electronic control systems to further enhance speed and direction control. These systems utilize sensors, actuators, and computer algorithms to monitor and adjust power distribution, shift points, and torque delivery based on various inputs, such as vehicle speed, throttle position, wheel slip, and road conditions. Electronic control systems enable precise and dynamic management of speed and direction variations, improving traction, fuel efficiency, and overall driveline performance.

By integrating transmissions, clutches, differentials, universal joints, CV joints, transfer cases, and electronic control systems, drivelines effectively handle variations in speed and direction during operation. These components and mechanisms work together to ensure smooth power transmission, optimized performance, and enhanced vehicle control in a wide range of driving conditions and applications.

What benefits do drivelines offer for different types of vehicles and equipment?

Drivelines offer several benefits for different types of vehicles and equipment across various industries. They play a critical role in power transmission, mobility, efficiency, and overall performance. Here’s a detailed explanation of the benefits drivelines offer for different types of vehicles and equipment:

1. Power Transmission: Drivelines are designed to efficiently transmit power from the engine or power source to the driven components, such as wheels, tracks, implements, or machinery. They ensure the smooth transfer of torque, allowing vehicles and equipment to generate the necessary power for propulsion, lifting, hauling, or other tasks. By effectively transmitting power, drivelines maximize the performance and productivity of vehicles and equipment.

2. Mobility and Maneuverability: Drivelines enable vehicles and equipment to achieve mobility and maneuverability across various terrains and working conditions. By transmitting power to the wheels or tracks, drivelines provide the necessary traction and control to overcome obstacles, navigate uneven surfaces, and operate in challenging environments. They contribute to the overall stability, handling, and agility of vehicles and equipment, allowing them to move efficiently and safely.

3. Versatility and Adaptability: Drivelines offer versatility and adaptability for different types of vehicles and equipment. They can be designed and configured to meet specific requirements, such as front-wheel drive, rear-wheel drive, four-wheel drive, or all-wheel drive systems. This flexibility allows vehicles and equipment to adapt to various operating conditions, including normal roads, off-road terrains, agricultural fields, construction sites, or industrial facilities. Drivelines also accommodate different power sources, such as internal combustion engines, electric motors, or hybrid systems, enhancing the adaptability of vehicles and equipment.

4. Efficiency and Fuel Economy: Drivelines contribute to efficiency and fuel economy in vehicles and equipment. They optimize power transmission by utilizing appropriate gear ratios, minimizing energy losses, and improving overall system efficiency. Drivelines with advanced technologies, such as continuously variable transmissions (CVTs) or automated manual transmissions (AMTs), can further enhance efficiency by continuously adjusting gear ratios based on load and speed conditions. Efficient driveline systems help reduce fuel consumption, lower emissions, and maximize the operational range of vehicles and equipment.

5. Load Carrying Capacity: Drivelines are designed to handle and transmit high torque and power, enabling vehicles and equipment to carry heavy loads. They incorporate robust components, such as heavy-duty axles, reinforced drive shafts, and durable differentials, to withstand the demands of load-bearing applications. Drivelines ensure the reliable transmission of power, allowing vehicles and equipment to transport materials, tow trailers, or carry payloads efficiently and safely.

6. Safety and Control: Drivelines contribute to safety and control in vehicles and equipment. They enable precise control over acceleration, deceleration, and speed, enhancing driver or operator confidence and maneuverability. Drivelines with features like traction control systems, limited-slip differentials, or electronic stability control provide additional safety measures by improving traction, stability, and handling in challenging road or operating conditions. By ensuring optimal power distribution and control, drivelines enhance the overall safety and stability of vehicles and equipment.

7. Durability and Reliability: Drivelines are built to withstand harsh operating conditions and provide long-term durability and reliability. They are engineered with high-quality materials, precise manufacturing processes, and advanced technologies to ensure the driveline components can endure the stresses of power transmission. Well-designed drivelines require minimal maintenance, reducing downtime and enhancing the overall reliability of vehicles and equipment.

8. Specialized Functionality: Drivelines offer specialized functionality for specific types of vehicles and equipment. For example, in off-road vehicles or heavy-duty construction equipment, drivelines with features like differential locks, torque vectoring, or adjustable suspension systems provide enhanced traction, stability, and control. In agricultural machinery, drivelines with power take-off (PTO) units enable the connection of various implements for specific tasks like plowing, seeding, or harvesting. Such specialized driveline features enhance the performance and versatility of vehicles and equipment in their respective applications.

In summary, drivelines provide numerous benefits for different types of vehicles and equipment. They ensure efficient power transmission, facilitate mobility and maneuverability, offer versatility and adaptability, contribute to efficiency and fuel economy, handle heavy loads, enhance safety and control, provide durability and reliability, and offer specialized functionality. By incorporating well-designed drivelines, manufacturers can optimize the performance, productivity, and overall functionality of vehicles and equipment across various industries.

editor by CX 2024-03-29

Polyurethane made in China – replacement parts – M900C250 Chain in Almaty Kazakhstan Roller for Conveyor Machinery with ce certificate top quality low price

We – EPG Group the greatest Chain and agricultural gearbox manufacturing facility in China with 5 different branches. For far more information: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

The new items incorporate a series of large-tech and substantial quality chains and sprockets and gears, this sort of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator phase-chains, higher-pace tooth chains, timing chains, self-lubrication chains, amongst which have sort substantial velocity tooth chain for automobile department dynamic box and aerial chains fill in the blanks of chain in China. Regular Owing to our sincerity in offering best provider to our customers, comprehending of your wants and overriding sense of responsibility toward filling purchasing needs,a specialized provider of a full variety of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….roller chain is obtainable with pitches from 1/2 to 3 inches. Chain figures are identified by multiplying the pitch by 80 (a 1/2 inch pitch chain would be a No. forty chain). A hyphenated suffix signifies numerous strands. The continued enlargement of our ball bearings, mounted models and power transmission merchandise lines, along with our attention to element and quality, has authorized EPG to gain wide acceptance to a assorted consumer base.

Solution Description

Wide Software

Our conveyor loafer can widely used for mining, coal ,metallurgy,electric electrical power, wharf and sea port, grain,chemical and almo EPT any industy which have conveying program.

Various kind of conveyor idlers:

one. Flat/Provider/Carrying Rollers: Employed to take care of bulk&device substance.

two.Effect Rollers: Set up at the loading position to absorb the shocks and to help shield again EPT belt injury.

three.Return Rollers: Used to maintain and assistance the belt during its return section and performs a cleaning motion

—Return rollers with Spaced Rings (Rubber Disc Rollers)

—Return Rollers with Helical Rubber Rings (Spiral Rollers)

four. Self-aligning/Education Rollers: Used to adju EPT the belt deviation, avoiding hunting and guaranteeing stable procedure of conveyor belt.

—Tapered self-aligning rollers

—Friction self-aligning rollers

Primary Characteristics:

- EPT sealing functionality

- Large load potential (axial load)

- Clean procedure, small revolving resistance, with no block phenomenon

- Effortless for disassembly, EPT maintainability and higher trustworthiness

- Powerful sturdiness, at lea EPT 50000 several hours operate life.

Specialized Parameter:

Idler Manufacturing Processing

Different Varieties of conveyor idler Group :

CE Certification

Our E EPT Undertaking in Mining, Coal, Energy Plant, Metallurgy, Metal Plant , Port & Wharf and EPT sector.

Company Introduction

HangZhou Xihu (West Lake) Dis.ng Hefty Market EPT Co., Ltd is specialized in planning , developing and manufacturing innovative and systematic conveying machinery such as belt conveyor, pipe conveyor, bucket elevator, screw conveyor, conveyor rollers, conveyor idlers, conveyor pulley, and a variety of varieties of elements related to the conveyors, which mostly applied for mining, coal, metallurgy, energy vegetation, dork, sea ports, grain, chemical, and EPT bulk materials transmission industries.

HangZhou Xihu (West Lake) Dis.ng established given that 2001 with complete registered cash of RMB 108 million, it addresses an spot of eighty,000 sq. meters with building spot of 26,000 sq. meters, current over 400 complex engineers and experienced staff. There are much more than a few hundreds sets of specialised manufacturing equipments and screening devices to assure for the superior technologies and large high quality.

Make contact with us:

Make contact with person: Merry Lee

Cell: +86~13083988828: -391-3955001 Phone: -18939191031

Tackle: Xihu (West Lake) Dis. Ea EPT Highway No.827, HangZhou,ZheJiang ,China

Web site:

The use of first tools manufacturer’s (OEM) portion figures or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our firm and the shown replacement parts contained herein are not sponsored, accepted, or manufactured by the OEM.

Customized made in China – replacement parts – roller chain sprockets custom manufacturer in Naberezhnye Tchelny Russian Federation Roller Chain Sprocket for Agricultural Machinery From China Manufacturer Scs with ce certificate top quality low price

We – EPG Group the biggest Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For a lot more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

Having accrued treasured expertise in cooperating with international customers, a specialised provider of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….ISO EPG is one of the greatest producers in China. We have superior devices for production and new technology tests potential . By means of adopting new engineering from British, German, U.S.A, our merchandise are best sellers all above European, The us, and Southeast Asia.9001:2000 & AS 9100B qualified custom maker of roller chains. Requirements of roller chains include .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. duration, 180 lbs. to 1529 lbs. tensile load capability & .035 lbs. to .276 lbs. bodyweight/ft. EPG major producer and provider of ball bearings and electrical power transmission tools. Given that it’s commencing in 1992, EPG has developed into one of the foremost suppliers in the industry. Crucial variables that have contributed to our expansion is our dedication to the fundamentals of modern style, competitive pricing, extraordinary client provider, and item availability. Customized roller chain sprocket for agricultural equipment from China manufacturer SCS

With much more than 20 years’ knowledge, high-precision equipment and strict administration technique, SCS can supply sprockets, gears, shafts, flanges and associated transmission areas for you with secure high quality and be EPT service.

Q1: What information will be very appreciated for a quotation?

A: It will be favored if you can offer us the drawings, heat treatment method and surface area remedy requirements, necessary quantity, quoted currency (USD or EUR), or samples.

Q2: Are you a trading organization or manufacturing unit?

A: SCS is a manufacturing facility positioned in HangZhou, ZheJiang .

Q3: What is your terms of payment?

A: T/T 50% in progress, and fifty% just before cargo. We will show you the pictures of the merchandise and packages before you spend the equilibrium.

Q4: Do you te EPT all your products ahead of delivery?

A: Indeed, SCS has adopted a rigid high quality management system and all the objects will be inspected according to the inspection instruction with great inspection documents.

Q5: Is there any consumer that has assessed your high quality administration system?

A:Indeed, SCS has handed the audit of many buyers, this kind of as Mitsubishi, CLAAS, Kardex and so on.

Q6: How does your organization make sure the quality of the raw material?

A: The stee EPT are purchased from our domestic well-acknowledged steel mills. Following obtaining the uncooked material, the steel will be inspected by spectrograph imported from Germany. Besides, the furnace quantity of steel will be properly-managed in our ERP system to make certain the traceablity of our products.

Q7: How do you ensure the substantial high quality of merchandise?

A: With integral producing processes, a rigorous top quality control system and imported devices, we can manufacture substantial good quality items.

Q8: What are your terms of shipping and delivery?

A: EXW, FOB ZheJiang .

Q9: How about your guide time?

A: Typically it will just take forty five days after obtaining your advance payment. The specific guide time depends on the things and the quantity of your get.

The use of unique gear manufacturer’s (OEM) part numbers or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our firm and the shown substitution components contained herein are not sponsored, accredited, or created by the OEM.

Best China manufacturer & factory multiple in Rajkot India processes machinery cnc stainless steel welding structural parts filter SS inlet port With high quality best price

More importantly, we make special components in accordance to provided drawings/samples and warmly welcome OEM inquiries.

Overview

Quick Information

- Relevant Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Provider:

-

Support

- Tolerance:

-

0Our patented coupling mechanism C Line is the end result of our information and advancement. It allows simple coupling and uncoupling of the PTO drive shaft. The include gives the consumer a lot more comfort and ease because of its ergonomically and compact kind. The users’ safety is certain, because he can’t get entangled in protruding parts of the yoke. There is also considerably less dust present at handling and there are fewer problems linked with it..01-.05mm or Customized

- Certification:

-

ISO9001, SGS

- Area Therapy:

-

Sandblasting,Sharpening,Anodize, Zinc,Nickel,Chrome,Plating, and many others.

- Application:

-

Car,Health-related Equipments,Electrical Appliance,Hardware,and so forth.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/4/Three Axis CNC Machining Middle

- Drawing Structure:

-

Professional/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Provide Capability

- Offer Capacity:

- 10000 Piece/Items per Thirty day period

Packaging & Shipping and delivery

- Port

- nb

-

Direct Time

: -

Amount(Pieces) one – five hundred >500 Est. Time(days) thirty To be negotiated

On the internet Customization

|

Merchandise Title |

numerous processes machinery cnc stainless steel welding structural components filter SS inlet port |

|

Product Kind |

CNC turning, milling, drilling, grinding, wire EDM slicing and so forth. |

|

Our Providers |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,and many others |

|

Content |

Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as for every the customers’ specifications |

|

Area Therapy |

Anodizing,Sandblasting,Portray,Powder coating,Plating,Silk Printing,Brushing,Sprucing,Laser Engraving |

|

Dimension |

As customers’ ask for |

|

Service Task |

To offer creation design and style, generation and specialized support, mould growth and processing, and so on |

|

Drawing Structure |

Pro/E, Vehicle CAD, Solid Functions,IGS,UG, CAD/CAM/CAE |

|

Testing Device |

Electronic Top Gauge, caliper, Coordinate measuring machine, projectiEPG Equipment is positioned in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport. on machine, roughness tester, hardness tester and so on |

|

Industry utilised |

Machinery heavy responsibility gear digital unit Car spare components optical telecommunication |

|

Packing |

Eco-helpful pp bag / EPE Foam /Carton boxes or wooden boxes |

|

Demo sample time |

7-ten times right after confirmation |

|

Supply time |

seven-30 times right after acquire the pre-payments |

|

Payment Terms |

T/T,Western Union,Paypal |

Best China manufacturer & factory agriculture in Albuquerque United States machinery heavy truck parts metal 700.46.30.012-1 B099 finger k700 With high quality best price

Our organization pays distinct consideration to customers’ needs, listening to the particular demands of each buyer and guaranteeing complete gratification.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Location of Origin:Zhejiang, China

- Model Title:

-

OEM

- Solution Name:

-

finger k700

- Substance:

-

Metal

- Application:

-

The quality of products is for us and for our consumers of higher significance. This is why we use European manufactured elements in our merchandise. We also complete continuous handle of incoming materials and the manage of finished items. In our business we function in accordance to ISO 9001.

K-seven hundred parts

- Certificate:

-

ISO9001:2008

- dimensions:

-

18*5.5*5.5cm

- Bodyweight:

-

2.14 kg

- Shipping and delivery time:

-

In 15 Days

- High quality:

-

one hundred%analyzed

-

OEM:

Adhering to “Survival by Quality, Growth by Technologies & Credit rating”, The company will consistently enhance solution overall performance to satisfy the escalating buyer needs in the arduous style of operate. -

seven hundred.46.30.012-one

- Package deal:

-

Carton

Offer Ability

- Offer Capacity:

- a hundred Piece/Items for each Day

Packaging & Delivery

- Port

- Tianjin xingang port, Lianyungang port. Yiwu port, Shanghai

It is wise to spend attention to this factor when the gear reducer output shaft is pushed as an alternative of becoming a driver. Bearing in thoughts that one of the attributes of this worm-equipment reducer is the fact that can not be axle-pushed by the output shaft (irreversibility), it is practically extremely hard to fulfill complete irreversibility conditions, due to exterior variables this kind of as vibrations, etcÖ This is why, when the software demands whole irreversibility, it is advisable to make use of exterior brakes with adequate energy to keep away from slipping.

-

Lead Time

: -

Amount(Baggage) 1 – fourteen 15 – a hundred and forty >140 Est. Time(times) 5 15 To be negotiated

Online Customization

Merchandise Description

|

Merchandise Title |

agriculture equipment heavy truck areas metallic seven-hundred.forty six.thirty.012-1 B099 finger k700 |

At any time-electrical power Group expert in producing all sorts of mechanical transmission and hydraulic transmission like: planetary gearboxes,worm gearboxes, in-line helical gear velocity reducers, parallel shaft helical equipment reducers, helical bevel reducers, helical worm equipment reducers, agricultural gearboxes, tractor gearboxes, vehicle gearboxes, pto shafts, particular reducer & relevant gear elements and other related items, sprockets, hydraulic technique, vacuum pumps, fluid coupling, equipment racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm gearboxes and so on. additionally, we can generate personalized variators, geared motors, electric motors and other hydraulic items according to customers’ drawings.

We gives a reputable grantee for the product’ s quality by advanced inspection and testing products. skilled specialized staff, beautiful processing engineering and stringent manage program. In latest years, the business has been creating rapidly by its abundant knowledge in creation, innovative management system, standardized administration technique, robust technological pressure. We constantly adhere the notion of survival by good quality, and advancement by innovation in science and technology.

Our Group is willing to operate with you hand in hand and produce brilliance jointly!

Relevant Items

Company Info

Get in touch with Us

Agricultural best made in China – replacement parts – tractor pto shaft accidents Machinery Self Propelled Boom Sprayer for Pesticide with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto manufacturing facility in China with 5 diverse branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

2007 cadillac cts drive shaft EPG 2004 toyota tacoma push shaft main bush hog sq720 slip clutch creation new holland tractor pto shaft is ebay pto push shaft of hydraulic pump pto farming c&t driveshaft fifteen-five hundred pto shaft locking pin horsepower weasler series 6 pto shaft tractor 2008 f250 rear push shaft supporting equipment, mechanical cultivation, harvesting machinery and accessories. Adhering to “Survival by High quality, Improvement by Technology & Credit rating”, The firm will consistently boost solution efficiency to fulfill the growing consumer requirements in the arduous style of work.

3WPZ-1200G variety self propelled spray boom sprayer

3WPZ-1200G sequence of sprayer is suitable for spraying the medicament for the planter of bean, corn, cotton, grain.

Also for lawn,fruiter,vegetable, street aspect tree. The ability could be 1200L, the spraying width could be 13.1-16m with 53hp.

Rewards:

•This kind of growth sprayer is a tractor mounted sprayer.

•Wide functioning scope,spraying for bean,cotton,corn etc.

•Wide spraying with to be 16m max.and the functioning angle of this tractor sprayer could be modified.

•The capability of mounted increase sprayer could be adjusted to fulfill different want from the user.

| Model | 3WPZ-1200G self-propelled spray growth sprayer | Pump Kind | Plunger pump |

| Engine Product | 4L68 (Changchai) turbocharged EPT engine | Pump Model | OS-5200 |

| Power / Velocity | 53 hp 2400r / min | Pump Stress | 0-45kgf/cm² |

| Displacement Stage | China III | Pump Stream | 220-240L / Min |

| Gear | Forward equipment 4,reverse gear 1 | Pump Velocity | 600-800r / min |

| Drive Manner | Four-wheel push | Tank Ability | 1500L |

| Steering Method | Hydraulic steering | Spray Height | 0.5-3. m |

| Mixing Method | Circulating water mixing | Nozzle Product | No.3 |

| Folding Method | Hydraulic folding | Spray Angle | 110° |

| Spray Width | 16 m | Nozzle Circulation | 1.2L / min |

| Vertical Peak | 1.8 m(customizable) | System Work Strain | 0.3-.5Mpa |

| Wheel Observe | 1.95-2.6 m(adjustable) | 3 Filtration Technique | Tank inlet, pump inlet, nozzle |

| Operating Efficiency | 21-thirty acres / hour | Battery | 12v / 120AH |

| Walking Speed | ≤25Km / h | Front Tire Product | Tractor tires 9.5-24 |

| Overall Dimension | 5800 mm x 2900 mm x 3700 mm | Rear Tire Design | Tractor tires 9.5-24 |

| Weight | 3811Kg | Water Tank | 15L |

Q:Are you a manufacturing unit or trading business?

A:We are a manufacturing facility.

Q: How does your manufacturing unit do relating to top quality manage?

A: Quality is precedence. we always say great value to high quality managing from the extremely beginning to the very stop.

Q: Do you have a solution accessory?

A: Yes, we have the accessories of the merchandise.

Q:Can you personalize the item?

A:We can personalize the solution.

Q: What’s your payment terms?

A: Payment terms is T/T or L/C,We accept all reasonable payment.

Q: How about delivery time of your machine?

A: The delivery time is in 60 working days. It depending your quantity.

OEM Custom made in China – replacement parts – 2009 jeep liberty front drive shaft ODM Pto Drive Cardan Transmission Shaft Tractor Parts for Agriculture Machinery with Ce Certificate with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto manufacturing facility in China with 5 various branches. For far more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

weasler fifty five collection pto shaft Our 2003 chevy silverado rear push shaft products a thousand to 540 adapter are sicma tiller pto shaft offering pto yoke elements effectively eg pto shafts in 2006 chevy equinox push shaft Chinese pto driveline shields marketplaces generate shaft ertiga and exterior pto shaft some merchandise marketed in worldwide markets are nicely obtained by Chinese and foreign clientele at home and abroad. EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm equipment cutting tools.

OEM ODM Pto Travel Cardan Transmission Shaft Tractor Elements for Agriculture Equipment with Ce Certification

one. Tubes or Pipes

We’ve currently received Triangular profile tube and Lemon profile tube for all the sequence we provide.

And we have some star tube, splined tube and other profile tubes needed by our consumers (for a specified series). (You should observe that our catalog doesnt have all the objects we create)

If you w EPT tubes other than triangular or lemon, please supply drawings or photographs.

2.Conclude yokes

We have obtained many kinds of fast release yokes and basic bore yoke. I will suggest the normal kind for your reference.

You can also send drawings or images to us if you are not able to find your merchandise in our catalog.

three. Security products or clutches

I will connect the detai EPT of security products for your reference. We’ve previously have Free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

four.For any other far more EPT demands with plastic guard, relationship approach, color of painting, package deal, and many others., remember to really feel cost-free to allow me know.

Characteristics:

1. We have been specialized in designing, producing push shaft, steering coupler shaft, common joints, which have exported to the Usa, Europe, Australia and so forth for years

2. Software to all varieties of standard mechanical situation

three. Our products are of large intensity and rigidity.

four. Warmth resist EPT & Acid resistant

five. OEM orders are welcomed

Our manufacturing facility is a top manufacturer of PTO shaft yoke and common joint.

We manufacture substantial quality PTO yokes for different vehicles, EPT machinery and gear. All goods are made with rotating lighter.

We are currently exporting our merchandise during the globe, specifically to North The usa, South America, Europe, and Russia. If you are interested in any item, make sure you do not be reluctant to get in touch with us. We are searching forward to turning into your suppliers in the near potential.

Best China manufacturer & factory High in Kinshasa Democratic Republic of the Congo precision customized cnc machinery part auto parts tools kit With high quality best price

We offer OEM service.

Overview

Quick Details

-

The company was certified by ISO9001:2008 Quality Management System.

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

BREATHER DESIGN Although there are dozens of stock breathers and vent plugs on the market, EPT testing found none to be totally effective under all operating conditions. Variables such as input/output speed, direction of rotation, oil level and viscosity, and reducer mounting position all affect breather performance.

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

High precision customized cnc machinery part auto parts tools kit

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer’s specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | EPG GROUP PTO shafts can be used for speeds up to 1000 rpm. The maximum working length of the PTO shafts varies according to the size of the tubes The range of the PTO shafts of RPG GROUP includes 4 series , according to the tube shape7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Service

OEM Parts

Surface Treatment

Production Process

Why Us

Electric made in China – replacement parts – in Palermo Italy Machinery Sprocket, Motor Sprocket, Gear, Plate Wheel Sprocket with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 various branches. For more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

We can supply Plate Wheel Sproket&comma Sprockets&comma sprocket for industrial use&comma industrial sprocket&comma sprocket wheel&comma pinion&comma sprocket wheel&comma chain wheel&comma black sprocket&comma iron sprocket&comma steel sprocket&comma c45 sprocket&comma ca EPT iron sprocket&comma aluminium sprocket&comma aluminum sprocket&comma alumina sprocket&comma copper sprocket&comma ss sprocket&comma stainless steel sprocket&comma ss304 sprocket&comma particular sprocket&comma sprocket with keyway&comma common sprocket&comma sprocket with spline&comma hardened sprocket&comma 06B sprocket&comma 08B sprocket&comma 10B sprocket&comma 12B sprocket&comma 16B sprocket&comma 20B sprocket&comma 24B sprocket&comma 28B sprocket&comma 32B sprocket&comma 36B sprocket&comma 40B sprocket&comma 48B sprocket&comma twenty five sprocket&comma 35 sprocket&comma forty sprocket&comma fifty sprocket&comma sixty sprocket&comma eighty sprocket&comma a hundred sprocket&comma 120 sprocket&comma 140 sprocket&comma one hundred sixty sprocket&comma 180 sprocket&comma 200 sprocket&comma 240 sprocket

Regular or special sprocket as per your drawing or sample available

1&period of time Rang of item

03&sol04&sol05B&sol06B&sol08B&sol10B&sol12B&sol16B&sol20B&sol24B&sol28B&sol32B

25&sol35&sol40&sol41&sol50&sol60&sol80&sol100&sol120&sol140&sol160&sol180&sol200&sol240

2&period Max&period Processing diameter&colon ø &equals1450mm

The sequence of completed-bore sprocket

1&period of time Rang of solution

06B&sol08B&sol10B&sol12B&sol16B&sol20B&sol

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160

two&time period Max&time period Processing diameter&colon ø &equals1450mm

Taper bore sprocket of BTL collection

one&period Rang of merchandise

06B&sol08B&sol10B&sol12B&sol16B&sol20B

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160

2&time period Max&period of time Processing diameter&colon ø &equals1450mm&period

Max&period of time Coordinated taper bush&colon 8065

Taper bore sprocket of QTL collection

1&interval Rang of item

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160&sol200

2&period of time Max&period of time Processing diameter&colon ø &equals1450mm&interval

Max&period of time Coordinated QD protect&colon N

STL taper bore sprocket

1&period Rang of merchandise

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160&sol200

2&period Max&period Processing diameter&colon ø &equals1450mm&period of time

Max&interval Coordinated Browning include&colon U2

Molten sprocket wheel

1&period Rang of solution

06B&sol08B&sol10B&sol12B&sol16B&sol20B&sol24B&lpartechnological-bore & BTL taper bore&rpar

We come to feel honoured to offer produced to get item&period

2&period of time Max&period Processing diameter&colon ø &equals1450mm&interval Max&time period Coordinated taper

Bush&colon 5050

3&period of time Max&time period Fat of the casting 2000kg&period of time

Coarse pitch conveyor sprocket

1&interval Rang of item

P50&solP75&solP100&solP50&period8

BTL taper bore sprocket of common sequence

1&period Rang of product

06B&sol08B&sol10B&sol12B&sol16B&sol20B

35&sol40&sol50&sol60&sol80&sol100&sol120&sol140&sol160

Flat-prime conveyor sprockets

one&period Rang of product

P 1&sol2″

Idle equipment

1&interval Rang of item

06B&sol08B&sol10B&sol12B&sol16B

35&sol40&sol41&sol50&sol60&sol80

Worm whee EPT &Worms

one&period of time Rang of item&lpar Module M1M3&comma Force angle20°

2&interval Rang of merchandise&lpar diametral pitch 4DP16PD&comma

Pressure angle14&period5°

Cylindrical spur gears

1&interval Rang of item&lpar Module M1M6&comma Stress angle20° Pierce

two&period Rang of solution&lpar diametral pitch 4DP16PD&comma Strain angle20° &sol14&period5° &period STL taper bore

Straight bevel gear

1&interval Rang of solution&lpar Module M1&period5M5&comma Force angle20° Pierce

2&interval Rang of solution&lpar diametral pitch 4DP16PD&comma Pressure angle20° &sol14&period5° STL taper bore

| Kind | 04B-48B |

| STHangZhouRD | American&commaEuropean Common |

| Substance | Steel |

| Area Treatment method | BLACKEN &commaZINC PLATED |

| Warmth TREATMENT | HARDEN |

The use of first products manufacturer’s (OEM) element figures or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our business and the listed alternative elements contained herein are not sponsored, accredited, or created by the OEM.