Product Description

| Basic Info. of Our Customized CNC Machining Parts | |

| Quotation | According To Your Drawings or Samples. (Size, Material, Thickness, Processing Content And Required Technology, etc.) |

| Tolerance | +/-0.005 – 0.01mm (Customizable) |

| Surface Roughness | Ra0.2 – Ra3.2 (Customizable) |

| Materials Available | Aluminum, Copper, Brass, Stainless Steel, Titanium, Iron, Plastic, Acrylic, PE, PVC, ABS, POM, PTFE etc. |

| Surface Treatment | Polishing, Surface Chamfering, Hardening and Tempering, Nickel plating, Chrome plating, zinc plating, Laser engraving, Sandblasting, Passivating, Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, etc. |

| Processing | Hot/Cold forging, Heat treatment, CNC Turning, Milling, Drilling and Tapping, Surface Treatment, Laser Cutting, Stamping, Die Casting, Injection Molding, etc. |

| Testing Equipment | Coordinate Measuring Machine (CMM) / Vernier Caliper/ / Automatic Height Gauge /Hardness Tester /Surface Roughness Teste/Run-out Instrument/Optical Projector, Micrometer/ Salt spray testing machine |

| Drawing Formats | PRO/E, Auto CAD, CZPT Works , UG, CAD / CAM / CAE, PDF |

| Our Advantages | 1.) 24 hours online service & quickly quote and delivery. 2.) 100% quality inspection (with Quality Inspection Report) before delivery. All our products are manufactured under ISO 9001:2015. 3.) A strong, professional and reliable technical team with 16+ years of manufacturing experience. 4.) We have stable supply chain partners, including raw material suppliers, bearing suppliers, forging plants, surface treatment plants, etc. 5.) We can provide customized assembly services for those customers who have assembly needs. |

| Available Material | |

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416, etc. |

| Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80, etc. |

| Copper | C11000, C12000,C12000, C36000 etc. |

| Aluminum | A380, AL2571, AL6061, Al6063, AL6082, AL7075, AL5052, etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP, PEI, Peek etc. |

| Others | Various types of Titanium alloy, Rubber, Bronze, etc. |

| Available Surface Treatment | |

| Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving, etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, etc. |

| Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, etc. |

| Plastic | Plating gold(ABS), Painting, Brushing(Acylic), Laser engraving, etc. |

FAQ:

Q1: Are you a trading company or a factory?

A1: We are a factory

Q2: How long is your delivery time?

A2: Samples are generally 3-7 days; bulk orders are 10-25 days, depending on the quantity and parts requirements.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples, and we will charge you based on sample processing. The sample fee can be refunded after placing an order in batches.

Q4: Do you provide design drawings service?

A4: We mainly customize according to the drawings or samples provided by customers. For customers who don’t know much about drawing, we also provide design and drawing services. You need to provide samples or sketches.

Q5: What about drawing confidentiality?

A5: The processed samples and drawings are strictly confidential and will not be disclosed to anyone else.

Q6: How do you guarantee the quality of your products?

A6: We have set up multiple inspection procedures and can provide quality inspection report before delivery. And we can also provide samples for you to test before mass production.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, RoHS, GS, ISO9001 |

|---|---|

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Metal |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Tolerance: | +/-0.005 – 0.01mm |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of driveline configurations based on vehicle type?

Yes, there are different types of driveline configurations based on the type of vehicle. Driveline configurations vary depending on factors such as the vehicle’s propulsion system, drivetrain layout, and the number of driven wheels. Here’s a detailed explanation of the driveline configurations commonly found in different vehicle types:

1. Front-Wheel Drive (FWD):

In front-wheel drive vehicles, the driveline configuration involves the engine’s power being transmitted to the front wheels. The engine, transmission, and differential are typically integrated into a single unit called a transaxle, which is located at the front of the vehicle. This configuration simplifies the drivetrain layout, reduces weight, and improves fuel efficiency. Front-wheel drive is commonly found in passenger cars, compact cars, and some crossover SUVs.

2. Rear-Wheel Drive (RWD):

Rear-wheel drive vehicles have their driveline configuration where the engine’s power is transmitted to the rear wheels. In this setup, the engine is located at the front of the vehicle, and the drivetrain components, including the transmission and differential, are positioned at the rear. Rear-wheel drive provides better weight distribution, improved handling, and enhanced performance characteristics, making it popular in sports cars, luxury vehicles, and large trucks.

3. All-Wheel Drive (AWD) and Four-Wheel Drive (4WD):

All-wheel drive and four-wheel drive driveline configurations involve power being transmitted to all four wheels of the vehicle. These configurations provide better traction and handling in various driving conditions, particularly on slippery or off-road surfaces. AWD systems distribute power automatically between the front and rear wheels, while 4WD systems are often manually selectable and include a transfer case for shifting between 2WD and 4WD modes. AWD and 4WD configurations are commonly found in SUVs, crossovers, trucks, and off-road vehicles.

4. Front Engine, Rear-Wheel Drive (FR) and Rear Engine, Rear-Wheel Drive (RR):

In certain performance vehicles and sports cars, driveline configurations may involve a front engine with rear-wheel drive (FR) or a rear engine with rear-wheel drive (RR). FR configurations have the engine located at the front of the vehicle, transmitting power to the rear wheels. RR configurations have the engine located at the rear, driving the rear wheels. These configurations provide excellent balance, weight distribution, and handling characteristics, resulting in enhanced performance and driving dynamics.

5. Other Configurations:

There are also various specialized driveline configurations based on specific vehicle types and applications:

- Mid-Engine: Some high-performance sports cars and supercars feature a mid-engine configuration, where the engine is positioned between the front and rear axles. This configuration offers exceptional balance, handling, and weight distribution.

- Front-Engine, Front-Wheel Drive (FF): While less common, certain compact and economy cars employ a front-engine, front-wheel drive configuration. This layout simplifies packaging and interior space utilization.

- Part-Time 4WD: In certain off-road vehicles, there may be a part-time 4WD driveline configuration. These vehicles typically operate in 2WD mode but can engage 4WD when additional traction is needed.

These are some of the driveline configurations commonly found in different vehicle types. The choice of driveline configuration depends on factors such as the vehicle’s intended use, performance requirements, handling characteristics, and specific design considerations.

How do drivelines contribute to the efficiency and performance of vehicle propulsion?

Drivelines play a crucial role in the efficiency and performance of vehicle propulsion systems. They are responsible for transmitting power from the engine to the wheels, converting rotational energy into forward motion. Drivelines contribute to efficiency and performance in several ways:

1. Power Transmission:

Drivelines efficiently transfer power from the engine to the wheels, ensuring that a significant portion of the engine’s output is converted into useful work. By minimizing power losses, drivelines maximize the efficiency of the propulsion system. High-quality driveline components, such as efficient transmissions and low-friction bearings, help optimize power transmission and reduce energy waste.

2. Gear Ratios:

Drivelines incorporate transmissions that allow for the selection of different gear ratios. Gear ratios match the engine’s torque and speed with the desired vehicle speed, enabling the engine to operate in its most efficient range. By optimizing the gear ratio based on the driving conditions, drivelines improve fuel efficiency and overall performance.

3. Torque Multiplication:

Drivelines can provide torque multiplication to enhance the vehicle’s performance during acceleration or when climbing steep gradients. Through the use of torque converters or dual-clutch systems, drivelines can increase the torque delivered to the wheels, allowing for quicker acceleration without requiring excessive engine power. Torque multiplication improves the vehicle’s responsiveness and enhances overall performance.

4. Traction and Control:

Drivelines contribute to vehicle performance by providing traction and control. Driveline components, such as differentials and limited-slip differentials, distribute torque between the wheels, improving traction and stability. This is particularly important in challenging driving conditions, such as slippery surfaces or off-road environments. By optimizing power delivery to the wheels, drivelines enhance vehicle control and maneuverability.

5. Handling and Stability:

Driveline configurations, such as front-wheel drive, rear-wheel drive, and all-wheel drive, influence the vehicle’s handling and stability. Drivelines distribute the weight of the vehicle and determine which wheels are driven. Different driveline setups offer distinct handling characteristics, such as improved front-end grip in front-wheel drive vehicles or enhanced cornering stability in rear-wheel drive vehicles. By optimizing the driveline configuration for the vehicle’s intended purpose, manufacturers can enhance handling and stability.

6. Hybrid and Electric Propulsion:

Drivelines are integral to hybrid and electric vehicle propulsion systems. In hybrid vehicles, drivelines facilitate the seamless transition between the engine and electric motor power sources, optimizing fuel efficiency and performance. In electric vehicles, drivelines transmit power from the electric motor(s) to the wheels, ensuring efficient and smooth acceleration. By incorporating drivelines specifically designed for hybrid and electric vehicles, manufacturers can maximize the efficiency and performance of these propulsion systems.

7. Weight Optimization:

Drivelines contribute to overall vehicle weight optimization. By using lightweight materials, such as aluminum or carbon fiber, in driveline components, manufacturers can reduce the overall weight of the propulsion system. Lighter drivelines help improve fuel efficiency, handling, and vehicle performance by reducing the vehicle’s mass and inertia.

8. Advanced Control Systems:

Modern drivelines often incorporate advanced control systems that enhance efficiency and performance. Electronic control units (ECUs) monitor various parameters, such as engine speed, vehicle speed, and driver inputs, to optimize power delivery and adjust driveline components accordingly. These control systems improve fuel efficiency, reduce emissions, and enhance overall drivability.

By optimizing power transmission, utilizing appropriate gear ratios, providing torque multiplication, enhancing traction and control, improving handling and stability, supporting hybrid and electric propulsion, optimizing weight, and incorporating advanced control systems, drivelines significantly contribute to the efficiency and performance of vehicle propulsion systems. Manufacturers continually strive to develop driveline technologies that further enhance these aspects, leading to more efficient and high-performing vehicles.

Which industries and vehicles commonly use drivelines for power distribution?

Drivelines are widely used in various industries and vehicles for power distribution. They play a crucial role in transmitting power from the engine or power source to the driven components, enabling motion and torque transfer. Here’s a detailed explanation of the industries and vehicles that commonly utilize drivelines for power distribution:

1. Automotive Industry: The automotive industry extensively utilizes drivelines in passenger cars, commercial vehicles, and off-road vehicles. Drivelines are a fundamental component of vehicles, enabling power transmission from the engine to the wheels. They are found in a range of vehicle types, including sedans, SUVs, pickup trucks, vans, buses, and heavy-duty trucks. Drivelines in the automotive industry are designed to provide efficient power distribution, enhance vehicle performance, and ensure smooth acceleration and maneuverability.

2. Agricultural Industry: Drivelines are essential in the agricultural industry for various farming machinery and equipment. Tractors, combines, harvesters, and other agricultural machinery rely on drivelines to transfer power from the engine to the wheels or tracks. Drivelines in agricultural equipment often incorporate power take-off (PTO) units, allowing the connection of implements such as plows, seeders, and balers. These drivelines are designed to handle high torque loads, provide traction in challenging field conditions, and facilitate efficient farming operations.

3. Construction and Mining Industries: Drivelines are extensively used in construction and mining equipment, where they enable power distribution and mobility in heavy-duty machinery. Excavators, bulldozers, wheel loaders, dump trucks, and other construction and mining vehicles rely on drivelines to transfer power from the engine to the wheels or tracks. Drivelines in these industries are designed to withstand rigorous operating conditions, deliver high torque and traction, and provide the necessary power for excavation, hauling, and material handling tasks.

4. Industrial Equipment: Various industrial equipment and machinery utilize drivelines for power distribution. This includes material handling equipment such as forklifts and cranes, industrial trucks, conveyor systems, and industrial vehicles used in warehouses, factories, and distribution centers. Drivelines in industrial equipment are designed to provide efficient power transmission, precise control, and maneuverability in confined spaces, enabling smooth and reliable operation in industrial settings.

5. Off-Road and Recreational Vehicles: Drivelines are commonly employed in off-road and recreational vehicles, including all-terrain vehicles (ATVs), side-by-side vehicles (UTVs), dirt bikes, snowmobiles, and recreational boats. These vehicles require drivelines to transfer power from the engine to the wheels, tracks, or propellers, enabling off-road capability, traction, and water propulsion. Drivelines in off-road and recreational vehicles are designed for durability, performance, and enhanced control in challenging terrains and recreational environments.

6. Railway Industry: Drivelines are utilized in railway locomotives and trains for power distribution and propulsion. They are responsible for transmitting power from the locomotive’s engine to the wheels or driving systems, enabling the movement of trains on tracks. Drivelines in the railway industry are designed to handle high torque requirements, ensure efficient power transfer, and facilitate safe and reliable train operation.

7. Marine Industry: Drivelines are integral components in marine vessels, including boats, yachts, ships, and other watercraft. Marine drivelines are used for power transmission from the engine to the propellers or water jets, providing thrust and propulsion. They are designed to withstand the corrosive marine environment, handle high torque loads, and ensure efficient power transfer for marine propulsion.

These are some of the industries and vehicles that commonly rely on drivelines for power distribution. Drivelines are versatile components that enable efficient power transmission, mobility, and performance across a wide range of applications, contributing to the functionality and productivity of various industries and vehicles.

editor by CX 2024-01-08

in Bandung Indonesia sales price shop near me near me shop factory supplier 28mm DC brushless electric motor for video conference devices manufacturer best Cost Custom Cheap wholesaler

EPG is a expert maker and exporter that is concerned with the layout, advancement and generation. ensures the security and regularity of the crucial perform of components. If you need any information or samples, please make contact with us and you will have our soon reply. 28mm dc brushless electrical motor for video clip meeting devices

Main Functions

one periodOEM solODM 28mm brushless motor

two periodLow noise commaLow daily life commaBuilt-in EPT commaEPT on commathen perform

three periodReverse rotation

4 periodPWM pace manage and FG sign opinions

five periodCan be obtainable with planetary EPT

| design no time period | Rated voltage | No-load velocity | No-load recent | Rated speed | Rated torque | Rated current | Output EPT | Stall torque | Stall recent |

| VDC | r solmin | mA | r solmin | g periodcm | mA | W | g periodcm | A | |

| TEC2847-0630 | six period0 | 3000 | 160 | 2000 | 110 | 620 | 2 period3 | 470 | 3 period2 |

| TEC2847-1240 | 12 period0 | 4000 | a hundred and twenty | 2700 | a hundred and forty | 450 | three period8 | 580 | 2 period9 |

| TEC2847-2465 | 24 period0 | 6500 | a hundred and eighty | 4800 | 180 | 600 | eight period9 | 720 | three period0 |

Solution Software

| Other Apps colon | |

| Enterprise EPTs colon | ATM comma Copiers and Scanners comma Forex Handling comma Point of Sale comma Printers comma Vending EPTs period |

| Food and EPTrage colon | EPTrage Dispensing comma Hand Blenders comma Blenders comma Mixers comma Espresso EPTs comma Food Processors comma Juicers comma Fryers comma Ice Makers comma Soy Bean Milk Makers time period |

| House EPTrtainment and Gaming colon | Gaming EPTs comma Movie Online games comma Optical Disk Drives comma RC and EPT Toys period |

| Home Technologies colon | Home Ventilation comma Air Purifiers and Dehumidifiers comma Assortment Hoods comma Washers and Dryers comma Refrigerators comma Dishwashers comma EPTr Treatment comma Whirlpool and Spa comma Showers comma Intelligent Metering comma Espresso EPTs period |

| Lawn and XiHu (West Lake) Dis.Hu (West Lake) Dis.den colon | Garden Mowers comma Snow Blowers comma Trimmers comma Leaf Blowers interval |

| Individual Care colon | Hair Chopping comma Hair Care comma Massagers time period |

| EPT Instruments colon | Drills and Drivers comma Sanders comma Grinders comma PoEPTrs comma Saws interval |

| Digital camera and Optical colon | Movie comma Cameras comma Projectors time period |

EPT amp Delivery

EPT colon single carton EPT comma a hundred parts per box period

EPT time colon

DHL colon three-5 doing work daEPT semi

UPS colon 5-7 functioning days semi

TNT colon five-seven doing work days semi

FedEx colon seven-nine operating times semi

EMS colon twelve-15 working times semi

By Sea colon Is dependent on which nation

Our Business

TT EPT lparHK rpar EPT Co time period comma Ltd has been EPTizing in micro motors comma EPT motors and their respective components considering that 2000 period

Our goods are widely used in EPTrtainment systems comma vehicles comma house and EPT EPTs and equipment and a lot of other folks interval Our goods are reliable and EPT-long lasting comma and backed by several years of experience period of time We export 98 percnt of our output throughout the world time period

By EPTaging our hard-received track record for honesty comma dependability and quality comma TT EPT aims to keep on as a pioneer in the revenue overEPT by looking for EPT partners interval If your firm is an stop-consumer of micro-motors comma a distributor or an agent comma remember to speak to us interval We seem EPT to currently being capable to work jointly with you in the in close proximity to EPT time period

FAQ

Q colon How to buy quest

A colon deliver us inquiry rightEPT EPT our quotation rightEPT negotiate particulars rightEPT confirm the sample rightEPT indicator contract soldeposit rightEPT mass production rightEPT cargo ready rightEPT stability soldelivery rightEPT additional cooperation period

Q colon How about Sample purchase quest

A colon Sample is offered for you interval make sure you contact us for particulars interval Contact us

Q colon Which transport way is avaliable quest

A colon DHL comma UPS comma FedEx comma TNT comma EMS comma EPT Put up commaSea are accessible periodThe other shipping and delivery waEPTare also offered comma please get in touch with us if you need ship by the other shipping way time period

Q colon How EPT is the supply quest

A colon Devliver time is dependent on the quantity you order time period generally it will take 15-25 doing work days interval

Q colon My package deal has missing goods time period What can I do quest

A colon Please contact our help team and we will confirm your orEPTwith the deal contents periodWe apologize for any inconveniences period

Q colon How to validate the payment quest

A colon We take payment by T solT comma PayPal comma the other payment waEPTalso could be accepted commaPlease speak to us just before you spend by the other payment approaches interval Also thirty-50 percnt deposit is available comma the equilibrium cash need to be compensated just before shipping and delivery interval

Best China manufacturer & factory Y2 in Abeokuta Nigeria Series Three Phase Induction Ac Electric Motor With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Model Number:

-

631-4/0.12KW

- Type:

-

Asynchronous Motor

- Frequency:

-

50HZ

- Phase:

-

three-phase

- Certification:

-

CCC, ce

- AC Voltage:

-

220/380V

Slip clutch: this type uses a slip clutch on the driven end yoke which is comprised of three steel plates in line held together with a series of bolts with springs under the nuts. The idea here is that when you tighten the nuts the pressure is increased onto the centre plate which when set up for the load will allow the shaft to turn and the implement to stall, absorbing the shock load. As mine is rated from 20-40 hp and I’m running a 17 hp I had to make alterations to set it up. Through trial and error I determined that I had to remove half the tension bolts and springs and back off the remainder nuts to minimum in order for the clutch to “slip” prior to stall on the tractor.

- Color:

-

Silverr plastic coating

- Product Name:

-

Y2 Series Ac Motor

We distribute many other items that are not listed above, but are still readily available. Feel free to give us a call or send us an email. We are always ready to help.

Supply Ability

- Supply Ability:

- 15000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Each in carton box,then packed in wooden case.

- Port

- NINGBO/SHANGHAI

Online Customization

The company was certified by ISO9001:2008 Quality Management System.

Y2 Series Three Phase Induction Ac Electric Motor

| Product Name | Y2 Series Three Phase Induction Ac Electric Motor |

| Color | Silverr plastic coating |

| frequency | 50HZ |

1. Can your factory accept OEM or ODM?

Yes,we have OEM & ODM for more than 22 years.

2.Can you offer sample?

Yes,we can offer Free samples for VIP.

3.How about your requirement for MOQ.?

We have very low requirement on Min. Order Quantity.

4.Do your factory offer quality warranty?

Yes,quality warrantee is guaranteed.

5.Do your factory offer trade assurance?

Certainly,we have trade assurance program support.

6.Do your factory accept distribution agent?

Yes, distribution agent is warmly welcomed.

Electric made in China – replacement parts – in Palermo Italy Machinery Sprocket, Motor Sprocket, Gear, Plate Wheel Sprocket with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 various branches. For more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

We can supply Plate Wheel Sproket&comma Sprockets&comma sprocket for industrial use&comma industrial sprocket&comma sprocket wheel&comma pinion&comma sprocket wheel&comma chain wheel&comma black sprocket&comma iron sprocket&comma steel sprocket&comma c45 sprocket&comma ca EPT iron sprocket&comma aluminium sprocket&comma aluminum sprocket&comma alumina sprocket&comma copper sprocket&comma ss sprocket&comma stainless steel sprocket&comma ss304 sprocket&comma particular sprocket&comma sprocket with keyway&comma common sprocket&comma sprocket with spline&comma hardened sprocket&comma 06B sprocket&comma 08B sprocket&comma 10B sprocket&comma 12B sprocket&comma 16B sprocket&comma 20B sprocket&comma 24B sprocket&comma 28B sprocket&comma 32B sprocket&comma 36B sprocket&comma 40B sprocket&comma 48B sprocket&comma twenty five sprocket&comma 35 sprocket&comma forty sprocket&comma fifty sprocket&comma sixty sprocket&comma eighty sprocket&comma a hundred sprocket&comma 120 sprocket&comma 140 sprocket&comma one hundred sixty sprocket&comma 180 sprocket&comma 200 sprocket&comma 240 sprocket

Regular or special sprocket as per your drawing or sample available

1&period of time Rang of item

03&sol04&sol05B&sol06B&sol08B&sol10B&sol12B&sol16B&sol20B&sol24B&sol28B&sol32B

25&sol35&sol40&sol41&sol50&sol60&sol80&sol100&sol120&sol140&sol160&sol180&sol200&sol240

2&period Max&period Processing diameter&colon ø &equals1450mm

The sequence of completed-bore sprocket

1&period of time Rang of solution

06B&sol08B&sol10B&sol12B&sol16B&sol20B&sol

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160

two&time period Max&time period Processing diameter&colon ø &equals1450mm

Taper bore sprocket of BTL collection

one&period Rang of merchandise

06B&sol08B&sol10B&sol12B&sol16B&sol20B

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160

2&time period Max&period of time Processing diameter&colon ø &equals1450mm&period

Max&period of time Coordinated taper bush&colon 8065

Taper bore sprocket of QTL collection

1&interval Rang of item

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160&sol200

2&period of time Max&period of time Processing diameter&colon ø &equals1450mm&interval

Max&period of time Coordinated QD protect&colon N

STL taper bore sprocket

1&period Rang of merchandise

35&sol40&sol41&sol&sol50&sol60&sol80&sol100&sol120&sol140&sol160&sol200

2&period Max&period Processing diameter&colon ø &equals1450mm&period of time

Max&interval Coordinated Browning include&colon U2

Molten sprocket wheel

1&period Rang of solution

06B&sol08B&sol10B&sol12B&sol16B&sol20B&sol24B&lpartechnological-bore & BTL taper bore&rpar

We come to feel honoured to offer produced to get item&period

2&period of time Max&period Processing diameter&colon ø &equals1450mm&interval Max&time period Coordinated taper

Bush&colon 5050

3&period of time Max&time period Fat of the casting 2000kg&period of time

Coarse pitch conveyor sprocket

1&interval Rang of item

P50&solP75&solP100&solP50&period8

BTL taper bore sprocket of common sequence

1&period Rang of product

06B&sol08B&sol10B&sol12B&sol16B&sol20B

35&sol40&sol50&sol60&sol80&sol100&sol120&sol140&sol160

Flat-prime conveyor sprockets

one&period Rang of product

P 1&sol2″

Idle equipment

1&interval Rang of item

06B&sol08B&sol10B&sol12B&sol16B

35&sol40&sol41&sol50&sol60&sol80

Worm whee EPT &Worms

one&period of time Rang of item&lpar Module M1M3&comma Force angle20°

2&interval Rang of merchandise&lpar diametral pitch 4DP16PD&comma

Pressure angle14&period5°

Cylindrical spur gears

1&interval Rang of item&lpar Module M1M6&comma Stress angle20° Pierce

two&period Rang of solution&lpar diametral pitch 4DP16PD&comma Strain angle20° &sol14&period5° &period STL taper bore

Straight bevel gear

1&interval Rang of solution&lpar Module M1&period5M5&comma Force angle20° Pierce

2&interval Rang of solution&lpar diametral pitch 4DP16PD&comma Pressure angle20° &sol14&period5° STL taper bore

| Kind | 04B-48B |

| STHangZhouRD | American&commaEuropean Common |

| Substance | Steel |

| Area Treatment method | BLACKEN &commaZINC PLATED |

| Warmth TREATMENT | HARDEN |

The use of first products manufacturer’s (OEM) element figures or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating item use and compatibility. Our business and the listed alternative elements contained herein are not sponsored, accredited, or created by the OEM.

Best China manufacturer & factory electric motor space heaters With high quality best price

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.Additionally, all our production procedures are in compliance with ISO9001 standards.

Overview

Quick Details

- Brand Name:

-

OEM

- Model Number:

-

9302

- Type:

-

Asynchronous Motor

- Frequency:

-

220

- Phase:

-

three-phase

-

Shear bolt torque limiter (SB) EPG GROUP offers high quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers

- Certification:

-

CCC, ce, ROHS

- Protect Feature:

-

Drip-Proof

Supply Ability

- Supply Ability:

- 10000 Box/Boxes per Day

Packaging & Delivery

- Packaging Details

- wooden case

- Port

- NingBo

Online Customization

electric motor space heaters

Ever-Power electirc motor factory is one of the biggest reducer and geared motor manufacturer in China,

main products range:

Worm geared motors

Helical geared motors

Planetary geared motors

cyclo gear motor

servo gear motor

| + Y2 series motors + Y series motors + YD series multi-speed motors + YS series motors + YC YL series motors + Y3 series motors + YEJ motors + Mortor components + TYGZ synchronous motors + TYBZ synchronous motors + Servo motors + Brushles dc motors + Electirc Motor + Rare-Earth-Permanent-Magnet motors(REPM MOTORS) |

Due to limitation of website, please kindly contact us for free catalog in case of need, do not hesitate to

inquire us with item + QTY. You will win in your market with our high quality and lower cost products…

Packaging & Shipping

Our Services

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, AMA , Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-Ø Our Company with over twelve year’s history and 1000 workers and 20 sales.

-Ø With over 100 Million USD sales in 2017

-Ø With advance machinery equipments

-Ø With large work capacity and high quality control, ISO certified.

……

you also can check our website to know for more details, if you need our products catalogue, please contact with us.

Company Information

|

|

|

|

|

|

|

|

|

The company was certified by ISO9001:2008 Quality Management System.

Material available |

Surface treatment |

Heat treatment |

|

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements. |

Blacking, galvanization, chroming, electrophoresis, color painting, … |

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, … |

Best China manufacturer & factory NMRV040 Worm gear reducer box speed reducer for electric motor With high quality best price

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.Additionally, all our production procedures are in compliance with ISO9001 standards.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Housing Material:

-

Aluminum Steel

- Certificate:

-

ISO9001

- Close up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage. Ratio:

-

5~300

- Bearing:

-

NSK Bearing

- Gear material:

-

45# Cast Steel

- Warranty:

-

1-2 Years

- Mounting Position:

-

Flange Mounted

- Output torque:

-

2.6-1195N.M

- Intput speed:

-

750~3000rpm

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 1 2 – 5 >5 Worm gears are the most compact type of system and provide high-ratio speed reduction. They are often the preferred type of gearing system when space is limited and large gear reductions are needed. Worm gears can be used to either greatly increase torque or greatly reduce speed. They are also the smoothest and quietest of the gear systems, as long as they are properly mounted and lubricated. Est. Time(days) 3 10 To be negotiated

Online Customization

Product Description

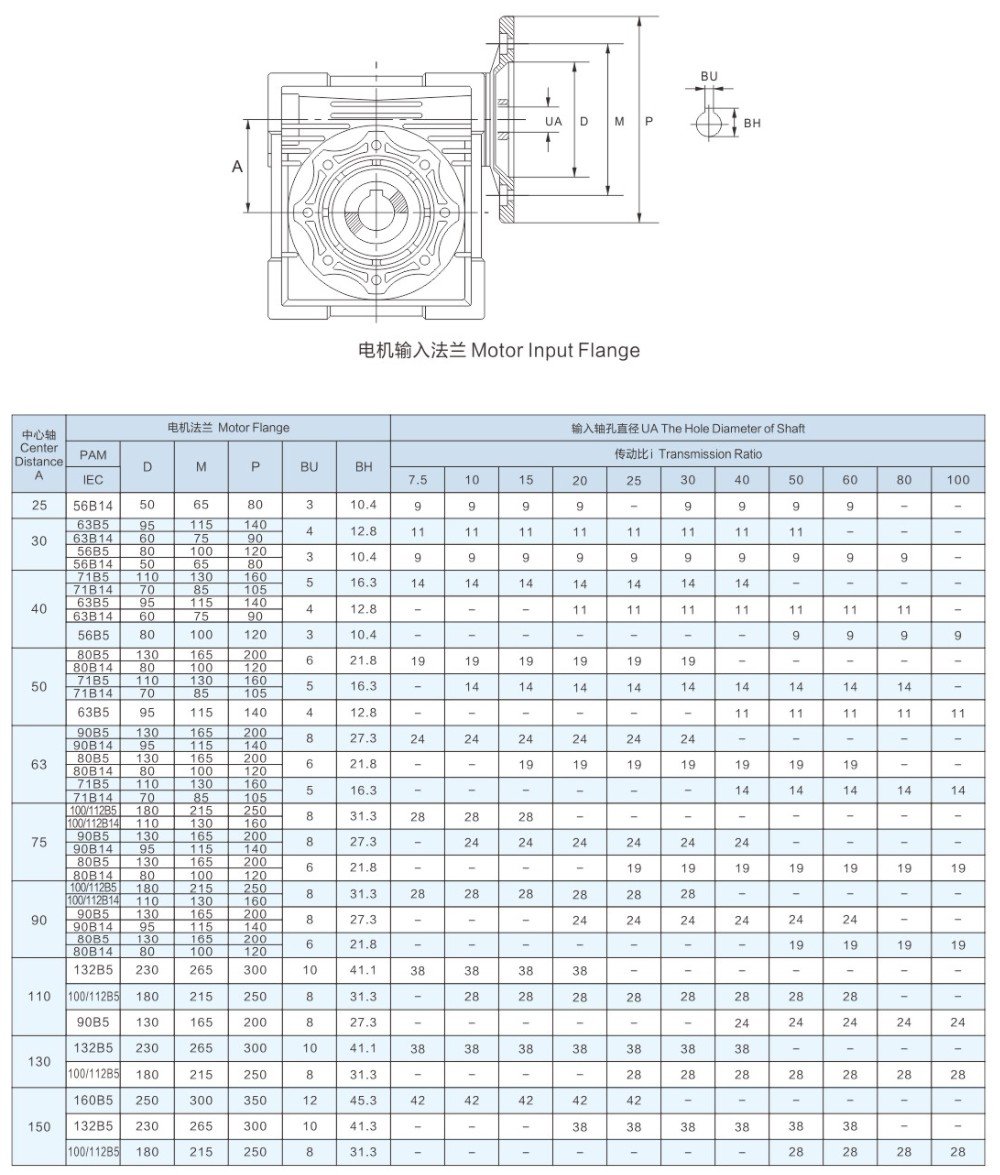

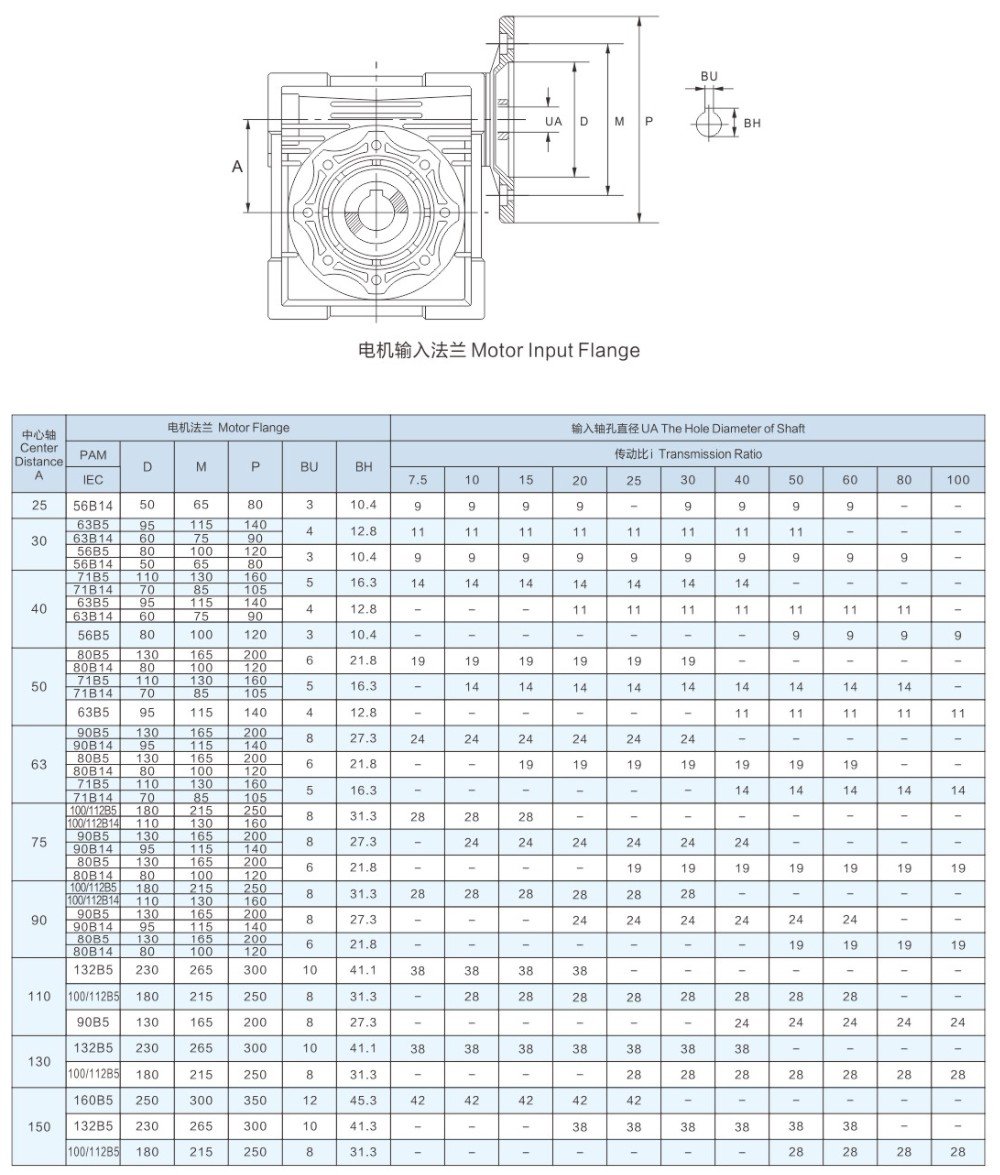

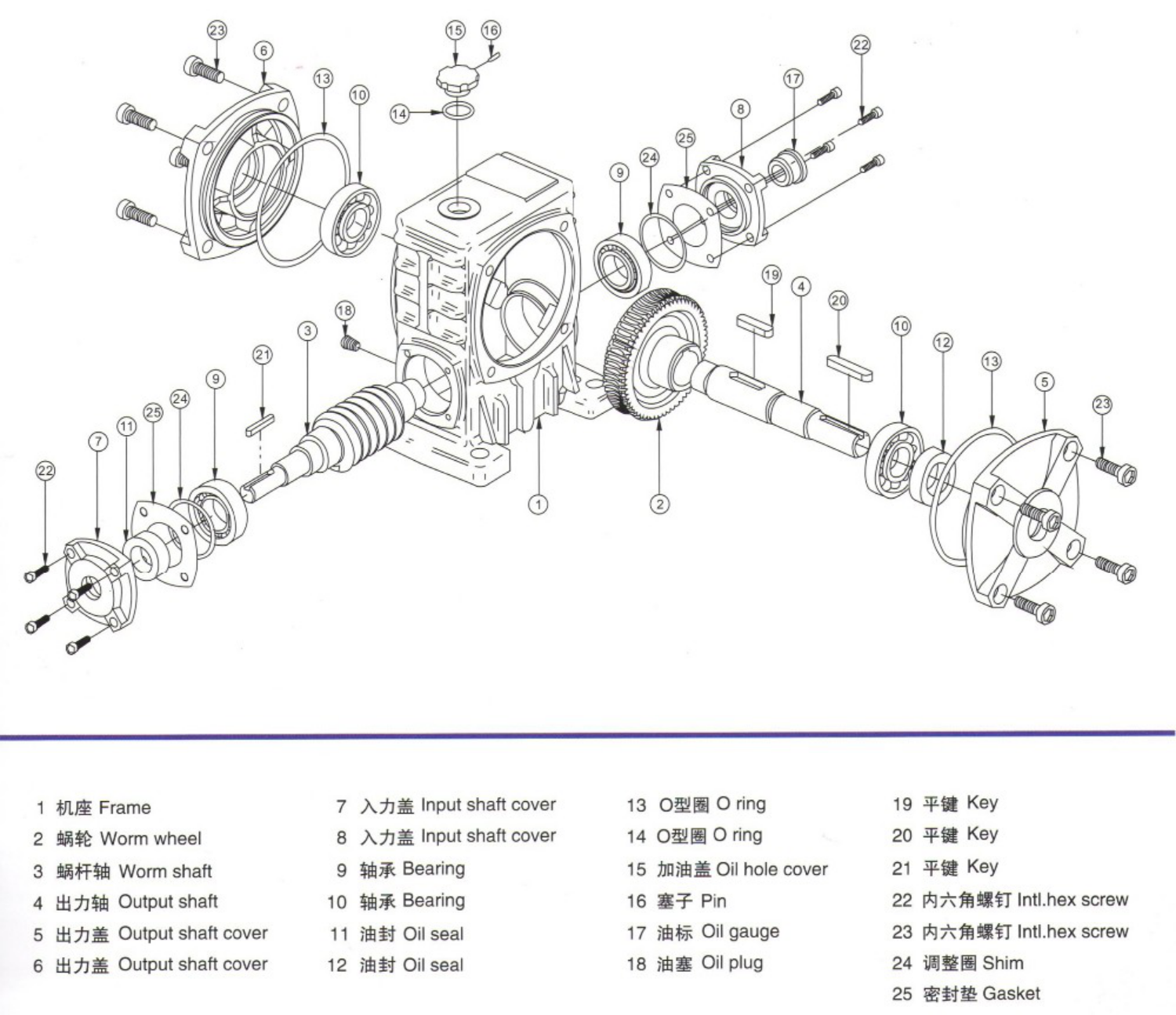

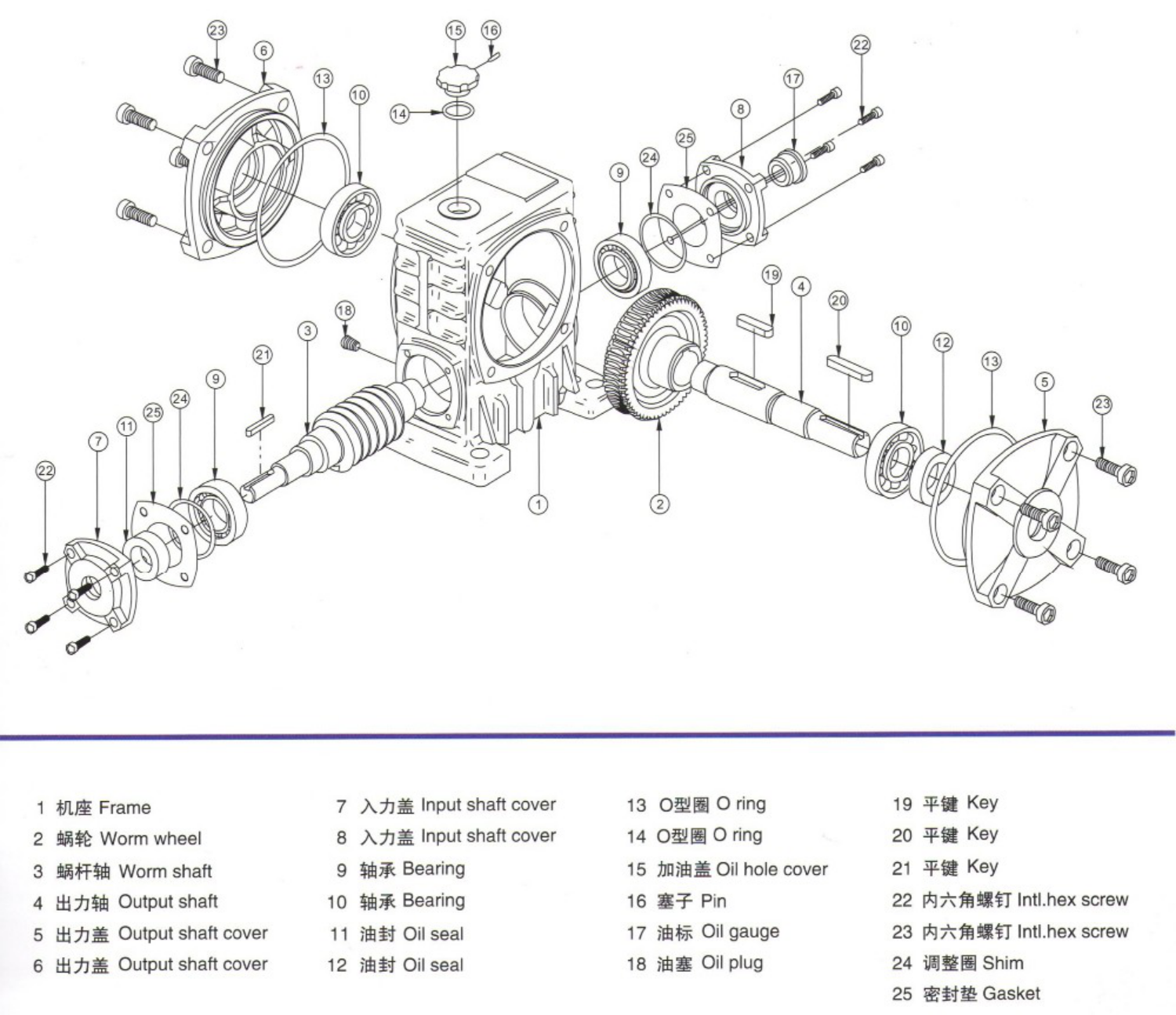

NMRV NRV SERIES WORM GEAR SPEED REDUCER

According to European standard of similar product,we adopt high-quality artificial oil,imported famous brand seal parts and manufacture technology to produce square multi-placed reductor. Feature beautiful appearance,easy installation,compact structure,low noise and high efficiency.

NMRV worm gear reducer absorbs advanced technology at home and abroad. It has a novel and unique “square box” external structure. The box is beautiful in shape and is made of high quality aluminium alloy by die casting.

NMRV Model & Marker

|

NMRV-063-30-VS-F1(FA)-AS-80B5-0.75KW-B3 |

||||||

|

NMRV |

Worm geared motor |

|||||

|

NRV |

Worm reduction unit |

|||||

|

063 |

center dictance |

|||||

|

30 |

Reduction ratio |

|||||

|

VS |

Double input shaft |

F1(FA) |

Output flange |

|||

|

AS |

Single output shaft |

AB |

Double output shaft |

|||

|

PAM |

Fitted for motor coupling |

80B5 |

Motor mounting facility |

|||

|

0.75KW |

Electric motor power |

B3 |

Mounting position |

|||

NMRV NRV SERIES WORM GEAR SPEED REDUCER FEATURES:

● The weight of the NMRV reducer is relatively light. The shell is made of aluminium alloy. It has the advantages of light weight, superior strength, exquisite appearance, high heat dissipation performance, long service life, no noise and so on. It is easy to connect with the motor.

● NMRV reducer is a more practical transmission equipment, and in the appearance design and its integration are more in line with the needs of the public than other types of reducers.

●The application field and popularity of theMain products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc. RV reducer made of aluminium alloy are even better than other types of reducer. It is a kind of reducer with high practicability, and also a combination of advanced technology at home and abroad.

● NMRV reducer is very convenient to connect with ordinary motor, CVT, flange electromagnetic clutch brake unit, and does not need coupling. Suitable for all-round installation, and the output torque is relatively large, work fairly smoothly and so on.

PRECISION BEVEL GEAR

20CrMn Ti material – low carbon alloy steel

Imported gear grinding machine processing, high hardness, stable performance.

Vacuum furnace carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL

The box body is made of HT200 material,which is cleaned by professional screening and washing equipment to ensure that the inner cavity of the box body is cleaner without iron filings.

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer

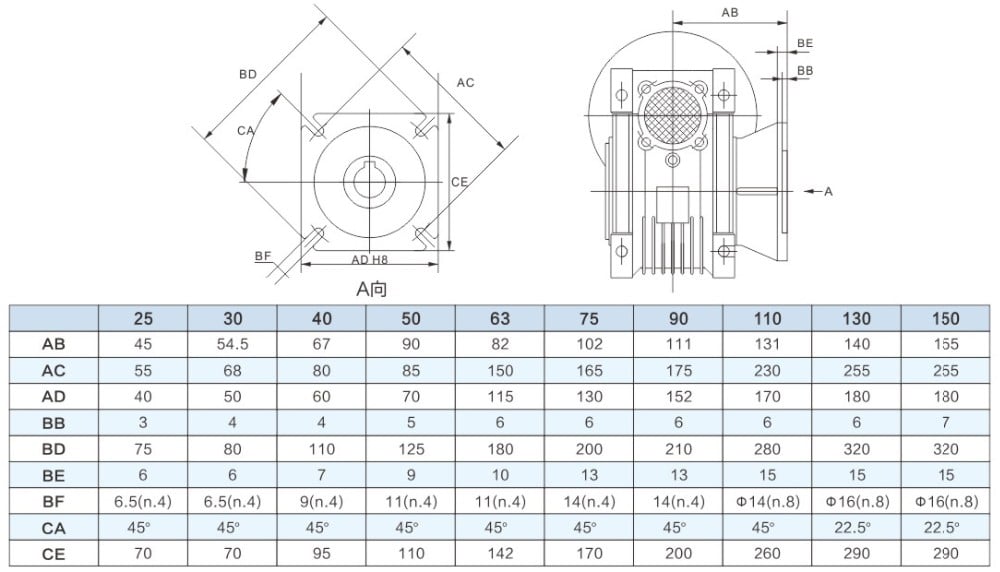

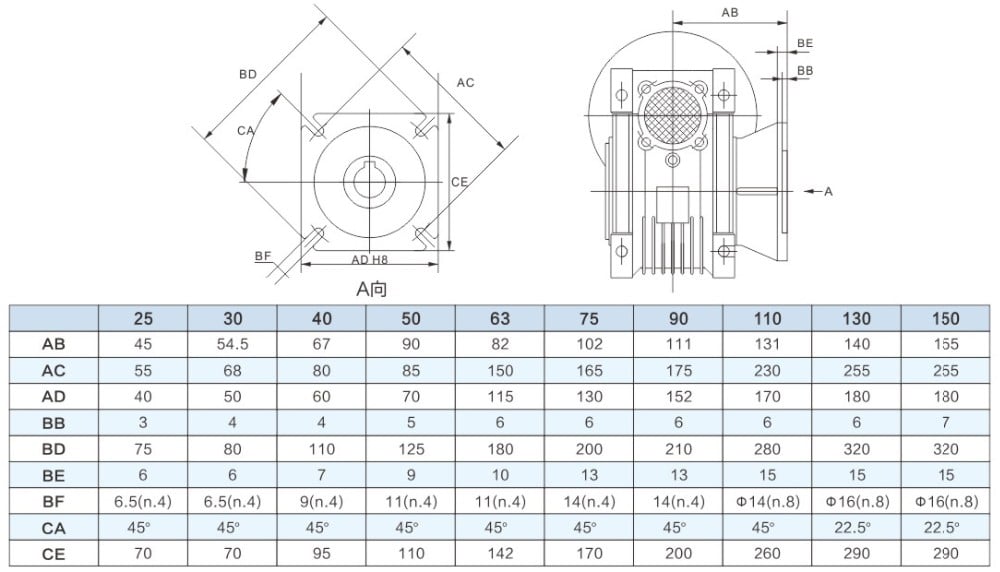

NMRV NRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Single Step Worm Gear Reducer

Output Flange Mounting Dimensions

Torque Arm Dimensions

|

Output Torque |

1.8-1760Nm |

|

Application |

Machinery Industry |

|

Gear Material |

Zepgn12-2 (BS-1400 GRADE-PB2) |

|

Input Speed |

900-2800RPM |

|

Output Speed |

10-250RPM |

Related product

Company Profile

Packing & Delivery