Product Description

| Basic Info. of Our Customized CNC Machining Parts | |

| Quotation | According To Your Drawings or Samples. (Size, Material, Thickness, Processing Content And Required Technology, etc.) |

| Tolerance | +/-0.005 – 0.01mm (Customizable) |

| Surface Roughness | Ra0.2 – Ra3.2 (Customizable) |

| Materials Available | Aluminum, Copper, Brass, Stainless Steel, Titanium, Iron, Plastic, Acrylic, PE, PVC, ABS, POM, PTFE etc. |

| Surface Treatment | Polishing, Surface Chamfering, Hardening and Tempering, Nickel plating, Chrome plating, zinc plating, Laser engraving, Sandblasting, Passivating, Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, etc. |

| Processing | Hot/Cold forging, Heat treatment, CNC Turning, Milling, Drilling and Tapping, Surface Treatment, Laser Cutting, Stamping, Die Casting, Injection Molding, etc. |

| Testing Equipment | Coordinate Measuring Machine (CMM) / Vernier Caliper/ / Automatic Height Gauge /Hardness Tester /Surface Roughness Teste/Run-out Instrument/Optical Projector, Micrometer/ Salt spray testing machine |

| Drawing Formats | PRO/E, Auto CAD, CZPT Works , UG, CAD / CAM / CAE, PDF |

| Our Advantages | 1.) 24 hours online service & quickly quote and delivery. 2.) 100% quality inspection (with Quality Inspection Report) before delivery. All our products are manufactured under ISO 9001:2015. 3.) A strong, professional and reliable technical team with 16+ years of manufacturing experience. 4.) We have stable supply chain partners, including raw material suppliers, bearing suppliers, forging plants, surface treatment plants, etc. 5.) We can provide customized assembly services for those customers who have assembly needs. |

| Available Material | |

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416, etc. |

| Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80, etc. |

| Copper | C11000, C12000,C12000, C36000 etc. |

| Aluminum | A380, AL2571, AL6061, Al6063, AL6082, AL7075, AL5052, etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, PP, PEI, Peek etc. |

| Others | Various types of Titanium alloy, Rubber, Bronze, etc. |

| Available Surface Treatment | |

| Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving, etc. |

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, etc. |

| Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, etc. |

| Plastic | Plating gold(ABS), Painting, Brushing(Acylic), Laser engraving, etc. |

FAQ:

Q1: Are you a trading company or a factory?

A1: We are a factory

Q2: How long is your delivery time?

A2: Samples are generally 3-7 days; bulk orders are 10-25 days, depending on the quantity and parts requirements.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples, and we will charge you based on sample processing. The sample fee can be refunded after placing an order in batches.

Q4: Do you provide design drawings service?

A4: We mainly customize according to the drawings or samples provided by customers. For customers who don’t know much about drawing, we also provide design and drawing services. You need to provide samples or sketches.

Q5: What about drawing confidentiality?

A5: The processed samples and drawings are strictly confidential and will not be disclosed to anyone else.

Q6: How do you guarantee the quality of your products?

A6: We have set up multiple inspection procedures and can provide quality inspection report before delivery. And we can also provide samples for you to test before mass production.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, RoHS, GS, ISO9001 |

|---|---|

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Metal |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Tolerance: | +/-0.005 – 0.01mm |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of driveline configurations based on vehicle type?

Yes, there are different types of driveline configurations based on the type of vehicle. Driveline configurations vary depending on factors such as the vehicle’s propulsion system, drivetrain layout, and the number of driven wheels. Here’s a detailed explanation of the driveline configurations commonly found in different vehicle types:

1. Front-Wheel Drive (FWD):

In front-wheel drive vehicles, the driveline configuration involves the engine’s power being transmitted to the front wheels. The engine, transmission, and differential are typically integrated into a single unit called a transaxle, which is located at the front of the vehicle. This configuration simplifies the drivetrain layout, reduces weight, and improves fuel efficiency. Front-wheel drive is commonly found in passenger cars, compact cars, and some crossover SUVs.

2. Rear-Wheel Drive (RWD):

Rear-wheel drive vehicles have their driveline configuration where the engine’s power is transmitted to the rear wheels. In this setup, the engine is located at the front of the vehicle, and the drivetrain components, including the transmission and differential, are positioned at the rear. Rear-wheel drive provides better weight distribution, improved handling, and enhanced performance characteristics, making it popular in sports cars, luxury vehicles, and large trucks.

3. All-Wheel Drive (AWD) and Four-Wheel Drive (4WD):

All-wheel drive and four-wheel drive driveline configurations involve power being transmitted to all four wheels of the vehicle. These configurations provide better traction and handling in various driving conditions, particularly on slippery or off-road surfaces. AWD systems distribute power automatically between the front and rear wheels, while 4WD systems are often manually selectable and include a transfer case for shifting between 2WD and 4WD modes. AWD and 4WD configurations are commonly found in SUVs, crossovers, trucks, and off-road vehicles.

4. Front Engine, Rear-Wheel Drive (FR) and Rear Engine, Rear-Wheel Drive (RR):

In certain performance vehicles and sports cars, driveline configurations may involve a front engine with rear-wheel drive (FR) or a rear engine with rear-wheel drive (RR). FR configurations have the engine located at the front of the vehicle, transmitting power to the rear wheels. RR configurations have the engine located at the rear, driving the rear wheels. These configurations provide excellent balance, weight distribution, and handling characteristics, resulting in enhanced performance and driving dynamics.

5. Other Configurations:

There are also various specialized driveline configurations based on specific vehicle types and applications:

- Mid-Engine: Some high-performance sports cars and supercars feature a mid-engine configuration, where the engine is positioned between the front and rear axles. This configuration offers exceptional balance, handling, and weight distribution.

- Front-Engine, Front-Wheel Drive (FF): While less common, certain compact and economy cars employ a front-engine, front-wheel drive configuration. This layout simplifies packaging and interior space utilization.

- Part-Time 4WD: In certain off-road vehicles, there may be a part-time 4WD driveline configuration. These vehicles typically operate in 2WD mode but can engage 4WD when additional traction is needed.

These are some of the driveline configurations commonly found in different vehicle types. The choice of driveline configuration depends on factors such as the vehicle’s intended use, performance requirements, handling characteristics, and specific design considerations.

How do drivelines contribute to the efficiency and performance of vehicle propulsion?

Drivelines play a crucial role in the efficiency and performance of vehicle propulsion systems. They are responsible for transmitting power from the engine to the wheels, converting rotational energy into forward motion. Drivelines contribute to efficiency and performance in several ways:

1. Power Transmission:

Drivelines efficiently transfer power from the engine to the wheels, ensuring that a significant portion of the engine’s output is converted into useful work. By minimizing power losses, drivelines maximize the efficiency of the propulsion system. High-quality driveline components, such as efficient transmissions and low-friction bearings, help optimize power transmission and reduce energy waste.

2. Gear Ratios:

Drivelines incorporate transmissions that allow for the selection of different gear ratios. Gear ratios match the engine’s torque and speed with the desired vehicle speed, enabling the engine to operate in its most efficient range. By optimizing the gear ratio based on the driving conditions, drivelines improve fuel efficiency and overall performance.

3. Torque Multiplication:

Drivelines can provide torque multiplication to enhance the vehicle’s performance during acceleration or when climbing steep gradients. Through the use of torque converters or dual-clutch systems, drivelines can increase the torque delivered to the wheels, allowing for quicker acceleration without requiring excessive engine power. Torque multiplication improves the vehicle’s responsiveness and enhances overall performance.

4. Traction and Control:

Drivelines contribute to vehicle performance by providing traction and control. Driveline components, such as differentials and limited-slip differentials, distribute torque between the wheels, improving traction and stability. This is particularly important in challenging driving conditions, such as slippery surfaces or off-road environments. By optimizing power delivery to the wheels, drivelines enhance vehicle control and maneuverability.

5. Handling and Stability:

Driveline configurations, such as front-wheel drive, rear-wheel drive, and all-wheel drive, influence the vehicle’s handling and stability. Drivelines distribute the weight of the vehicle and determine which wheels are driven. Different driveline setups offer distinct handling characteristics, such as improved front-end grip in front-wheel drive vehicles or enhanced cornering stability in rear-wheel drive vehicles. By optimizing the driveline configuration for the vehicle’s intended purpose, manufacturers can enhance handling and stability.

6. Hybrid and Electric Propulsion:

Drivelines are integral to hybrid and electric vehicle propulsion systems. In hybrid vehicles, drivelines facilitate the seamless transition between the engine and electric motor power sources, optimizing fuel efficiency and performance. In electric vehicles, drivelines transmit power from the electric motor(s) to the wheels, ensuring efficient and smooth acceleration. By incorporating drivelines specifically designed for hybrid and electric vehicles, manufacturers can maximize the efficiency and performance of these propulsion systems.

7. Weight Optimization:

Drivelines contribute to overall vehicle weight optimization. By using lightweight materials, such as aluminum or carbon fiber, in driveline components, manufacturers can reduce the overall weight of the propulsion system. Lighter drivelines help improve fuel efficiency, handling, and vehicle performance by reducing the vehicle’s mass and inertia.

8. Advanced Control Systems:

Modern drivelines often incorporate advanced control systems that enhance efficiency and performance. Electronic control units (ECUs) monitor various parameters, such as engine speed, vehicle speed, and driver inputs, to optimize power delivery and adjust driveline components accordingly. These control systems improve fuel efficiency, reduce emissions, and enhance overall drivability.

By optimizing power transmission, utilizing appropriate gear ratios, providing torque multiplication, enhancing traction and control, improving handling and stability, supporting hybrid and electric propulsion, optimizing weight, and incorporating advanced control systems, drivelines significantly contribute to the efficiency and performance of vehicle propulsion systems. Manufacturers continually strive to develop driveline technologies that further enhance these aspects, leading to more efficient and high-performing vehicles.

Which industries and vehicles commonly use drivelines for power distribution?

Drivelines are widely used in various industries and vehicles for power distribution. They play a crucial role in transmitting power from the engine or power source to the driven components, enabling motion and torque transfer. Here’s a detailed explanation of the industries and vehicles that commonly utilize drivelines for power distribution:

1. Automotive Industry: The automotive industry extensively utilizes drivelines in passenger cars, commercial vehicles, and off-road vehicles. Drivelines are a fundamental component of vehicles, enabling power transmission from the engine to the wheels. They are found in a range of vehicle types, including sedans, SUVs, pickup trucks, vans, buses, and heavy-duty trucks. Drivelines in the automotive industry are designed to provide efficient power distribution, enhance vehicle performance, and ensure smooth acceleration and maneuverability.

2. Agricultural Industry: Drivelines are essential in the agricultural industry for various farming machinery and equipment. Tractors, combines, harvesters, and other agricultural machinery rely on drivelines to transfer power from the engine to the wheels or tracks. Drivelines in agricultural equipment often incorporate power take-off (PTO) units, allowing the connection of implements such as plows, seeders, and balers. These drivelines are designed to handle high torque loads, provide traction in challenging field conditions, and facilitate efficient farming operations.

3. Construction and Mining Industries: Drivelines are extensively used in construction and mining equipment, where they enable power distribution and mobility in heavy-duty machinery. Excavators, bulldozers, wheel loaders, dump trucks, and other construction and mining vehicles rely on drivelines to transfer power from the engine to the wheels or tracks. Drivelines in these industries are designed to withstand rigorous operating conditions, deliver high torque and traction, and provide the necessary power for excavation, hauling, and material handling tasks.

4. Industrial Equipment: Various industrial equipment and machinery utilize drivelines for power distribution. This includes material handling equipment such as forklifts and cranes, industrial trucks, conveyor systems, and industrial vehicles used in warehouses, factories, and distribution centers. Drivelines in industrial equipment are designed to provide efficient power transmission, precise control, and maneuverability in confined spaces, enabling smooth and reliable operation in industrial settings.

5. Off-Road and Recreational Vehicles: Drivelines are commonly employed in off-road and recreational vehicles, including all-terrain vehicles (ATVs), side-by-side vehicles (UTVs), dirt bikes, snowmobiles, and recreational boats. These vehicles require drivelines to transfer power from the engine to the wheels, tracks, or propellers, enabling off-road capability, traction, and water propulsion. Drivelines in off-road and recreational vehicles are designed for durability, performance, and enhanced control in challenging terrains and recreational environments.

6. Railway Industry: Drivelines are utilized in railway locomotives and trains for power distribution and propulsion. They are responsible for transmitting power from the locomotive’s engine to the wheels or driving systems, enabling the movement of trains on tracks. Drivelines in the railway industry are designed to handle high torque requirements, ensure efficient power transfer, and facilitate safe and reliable train operation.

7. Marine Industry: Drivelines are integral components in marine vessels, including boats, yachts, ships, and other watercraft. Marine drivelines are used for power transmission from the engine to the propellers or water jets, providing thrust and propulsion. They are designed to withstand the corrosive marine environment, handle high torque loads, and ensure efficient power transfer for marine propulsion.

These are some of the industries and vehicles that commonly rely on drivelines for power distribution. Drivelines are versatile components that enable efficient power transmission, mobility, and performance across a wide range of applications, contributing to the functionality and productivity of various industries and vehicles.

editor by CX 2024-01-08

China Custom OEM High Precision CNC Stainless Steel Gear Shaft for Oli Pump Motor drive shaft parts

Product Description

Product Description

Product Parameters

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Axis Shape: | Straight Shaft |

| Appearance Shape: | Round |

| Rotation: | Cw |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is a driveshaft and how much does it cost to replace one?

Your vehicle is made up of many moving parts. Knowing each part is important because a damaged driveshaft can seriously damage other parts of the car. You may not know how important your driveshaft is, but it’s important to know if you want to fix your car. In this article, we’ll discuss what a driveshaft is, what its symptoms are, and how much it costs to replace a driveshaft.

Repair damaged driveshafts

A damaged driveshaft does not allow you to turn the wheels freely. It also exposes your vehicle to higher repair costs due to damaged driveshafts. If the drive shaft breaks while the car is in motion, it may cause a crash. Also, it can significantly affect the performance of the car. If you don’t fix the problem right away, you could risk more expensive repairs. If you suspect that the drive shaft is damaged, do the following.

First, make sure the drive shaft is protected from dust, moisture, and dust. A proper driveshaft cover will prevent grease from accumulating in the driveshaft, reducing the chance of further damage. The grease will also cushion the metal-to-metal contact in the constant velocity joints. For example, hitting a soft material is better than hitting a metal wall. A damaged prop shaft can not only cause difficult cornering, but it can also cause the vehicle to vibrate, which can further damage the rest of the drivetrain.

If the driveshaft is damaged, you can choose to fix it yourself or take it to a mechanic. Typically, driveshaft repairs cost around $200 to $300. Parts and labor may vary based on your vehicle type and type of repair. These parts can cost up to $600. However, if you don’t have a mechanical background, it’s better to leave it to a professional.

If you notice that one of the two drive shafts is worn, it’s time to repair it. Worn bushings and bearings can cause the drive shaft to vibrate unnecessarily, causing it to break and cause further damage. You can also check the center bearing if there is any play in the bearing. If these symptoms occur, it is best to take your car to a mechanic as soon as possible.

Learn about U-joints

While most vehicles have at least one type of U-joint, there are other types available. CV joints (also known as hot rod joints) are used in a variety of applications. The minor axis is shorter than the major axis on which the U-joint is located. In both cases, the U-joints are lubricated at the factory. During servicing, the drive shaft slip joint should be lubricated.

There are two main styles of U-joints, including forged and press fit. They are usually held in place by C-clamps. Some of these U-joints have knurls or grooves. When selecting the correct fitting, be sure to measure the entire fitting. To make sure you get the correct size, you can use the size chart or check the manual for your specific model.

In addition to lubrication, the condition of the U-joint should be checked regularly. Lubricate them regularly to avoid premature failure. If you hear a clicking sound when shifting gears, the u-joint space may be misaligned. In this case, the bearing may need to be serviced. If there is insufficient grease in the bearings, the universal joint may need to be replaced.

U-joint is an important part of the automobile transmission shaft. Without them, your car would have no wheeled suspension. Without them, your vehicle will have a rickety front end and a wobbly rear end. Because cars can’t drive on ultra-flat surfaces, they need flexible driveshafts. The U-joint compensates for this by allowing it to move up and down with the suspension.

A proper inspection will determine if your u-joints are loose or worn. It should be easy to pull them out. Make sure not to pull them all the way out. Also, the bearing caps should not move. Any signs of roughness or wear would indicate a need for a new UJ. Also, it is important to note that worn UJs cannot be repaired.

Symptoms of Driveshaft Failure

One of the most common problems associated with a faulty driveshaft is difficulty turning the wheels. This severely limits your overall control over the vehicle. Fortunately, there are several symptoms that could indicate that your driveshaft is failing. You should take immediate steps to determine the cause of the problem. One of the most common causes of driveshaft failure is a weak or faulty reverse gear. Other common causes of driveshaft damage include driving too hard, getting stuck in reverse gear and differential lock.

Another sign of a failed driveshaft is unusual noise while driving. These noises are usually the result of wear on the bushings and bearings that support the drive shaft. They can also cause your car to screech or scratch when switching from drive to idle. Depending on the speed, the noise may be accompanied by vibration. When this happens, it’s time to send your vehicle in for a driveshaft replacement.

One of the most common symptoms of driveshaft failure is noticeable jitter when accelerating. This could be a sign of a loose U-joint or worn center bearing. You should thoroughly inspect your car to determine the cause of these sounds and corresponding symptoms. A certified mechanic can help you determine the cause of the noise. A damaged propshaft can severely limit the drivability of the vehicle.

Regular inspection of the drive shaft can prevent serious damage. Depending on the damage, you can replace the driveshaft for anywhere from $500 to $1,000. Depending on the severity of the damage and the level of repair, the cost will depend on the number of parts that need to be replaced. Do not drive with a bad driveshaft as it can cause a serious crash. There are several ways to avoid this problem entirely.

The first symptom to look for is a worn U-joint. If the U-joint comes loose or moves too much when trying to turn the steering wheel, the driveshaft is faulty. If you see visible rust on the bearing cap seals, you can take your car to a mechanic for a thorough inspection. A worn u-joint can also indicate a problem with the transmission.

The cost of replacing the drive shaft

Depending on your state and service center, a driveshaft repair can cost as little as $300 or as high as $2,000, depending on the specifics of your car. Labor costs are usually around $70. Prices for the parts themselves range from $400 to $600. Labor costs also vary by model and vehicle make. Ultimately, the decision to repair or replace the driveshaft will depend on whether you need a quick car repair or a full car repair.

Some cars have two separate driveshafts. One goes to the front and the other goes to the back. If your car has four wheel drive, you will have two. If you’re replacing the axles of an all-wheel-drive car, you’ll need a special part for each axle. Choosing the wrong one can result in more expensive repairs. Before you start shopping, you should know exactly how much it will cost.

Depending on the type of vehicle you own, a driveshaft replacement will cost between PS250 and PS500. Luxury cars can cost as much as PS400. However, for safety and the overall performance of the car, replacing the driveshaft may be a necessary repair. The cost of replacing a driveshaft depends on how long your car has been on the road and how much wear and tear it has experienced. There are some symptoms that indicate a faulty drive shaft and you should take immediate action.

Repairs can be expensive, so it’s best to hire a mechanic with experience in the field. You’ll be spending hundreds of dollars a month, but you’ll have peace of mind knowing the job will be done right. Remember that you may want to ask a friend or family member to help you. Depending on the make and model of your car, replacing the driveshaft is more expensive than replacing the parts and doing it yourself.

If you suspect that your drive shaft is damaged, be sure to fix it as soon as possible. It is not advisable to drive a car with abnormal vibration and sound for a long time. Fortunately, there are some quick ways to fix the problem and avoid costly repairs later. If you’ve noticed the symptoms above, it’s worth getting the job done. There are many signs that your driveshaft may need service, including lack of power or difficulty moving the vehicle.

editor by CX 2023-05-25

in Asuncion Paraguay sales price shop near me near me shop factory supplier Planet Gear Motor for Solar Tracker manufacturer best Cost Custom Cheap wholesaler

EPG was awarded with “renowned product of Zhejiang Province” and “well-known manufacturer of Zhejiang Province”. EPG has set up a comprehensive established of good quality administration method which is supplied with innovative inspection and check products. EPG has been productively certified by ISO9002 Good quality Management System, ISO9001 Quality Administration Program, API certificate, ISO/TS16949:2002 and ISO10012 measurement management method. Planet Gear EPT for EPT Tracker

Product Description

one)Technical specs:

Use voltage variety:.5-9V

Rated Votage: three.0V

Reduction Ratio: 102

Specification of 10mm plastic planetary EPT motor

| Model | Application Parameters | Rated Torque of Equipment Box | Instantaneous Torque of Equipment Box | Equipment Ratio | Gear Box Length L1 |

|||||||

| Rated | At No Load | At Rated Load | Total Size L |

|||||||||

| Voltage | Velocity | Recent | Velocity | Current | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWBPD571571-28 | 3. | 617 | 70 | 518 | 215 | 36 | three.five | 27.8 | 1300 | 4000 | 28 | 12.8 |

| ZWBPD571571-forty six | 3. | 375 | 80 | 315 | 215 | 39 | three.eight | 30.nine | 1300 | 4000 | forty six | fifteen.nine |

| ZWBPD571571-sixty nine | 3. | 250 | eighty | 210 | 215 | fifty eight | 5.7 | 1300 | 4000 | 69 | ||

| ZWBPD571571-102 | 3. | 169 | eighty | 142 | 215 | 86 | 8.4 | 1300 | 4000 | 102 | ||

| ZWBPD571571-151 | 3. | 114 | 80 | ninety six | 215 | 127 | 12.5 | 1300 | 4000 | 151 | ||

| ZWBPD571571-168 | 3. | 98 | eighty | 86 | 220 | 106 | ten.4 | 34 | 1300 | 4000 | 168 | 19 |

| ZWBPD571571-249 | three. | 66 | 80 | fifty eight | 220 | 158 | 15 | 1300 | 4000 | 249 | ||

| ZWBPD571571-368 | 3. | 45 | 80 | 39 | 220 | 233 | 23 | 1300 | 4000 | 368 | ||

above specs just for reference and customizable according to requirements.

Second Drawing

Solution specifics demonstrate:

Application

| Intelligent wearable units | look at,VR,AR,XR and and so forth. |

| EPT application | kitchen EPTs, sewing EPTs, corn popper, EPT cleaner, XiHu (West Lake) Dis.Hu (West Lake) Dis.den resource, sanitary ware, window curtain, EPT closestool, sweeping robot, EPT seat, stXiHu (West Lake) Dis.Hu (West Lake) Dis. desk, electric sofa, Tv set, laptop, treadmill, spyhole, cooker hood, electric powered drawer, electric mosquito net, EPT cabinet, EPT wardrobe, automated soap dispenser, EPTbaby bottle sterilizer, lifting scorching pot cookware, dishwasher, washing EPT, meals breaking EPT, dryer, air conditioning, dustbin, espresso EPT, whisk,intelligent lock,bread maker,Window cleaning robot and and so forth. |

| conversation gear | 5G foundation station,video clip convention,cell telephone and and so forth. |

| Workplace EPT equipments | scanners, printers, multifunction EPTs duplicate EPTs, fax (FAX paper cutter), computer peripheral, financial institution EPT, EPT, lifting socket, show,notebook Pc and and many others. |

| EPTmotive items | conditioning damper actuator, auto DVD,door lock actuator, retractable rearview mirror, meters, optic aXiHu (West Lake) Dis.s manage system, head ligEPT beam degree adjuster, vehicle water pump, vehicle antenna, lumbar help, EPB, automobile tail gate electric powered putter, HUD, head-up display, vehicle sunroof, EPS, AGS, vehicle window, head restraint, E-booster, auto seat, vehicle charging station and and so on. |

| ToEPTand models | radio manage product, automatic cruise manage, experience-on toy, educational robot, programming robot, health care robotic, automatic feeder, EPT constructing blocks, escort robotic and and so forth. |

| Health care equipments | blood stress meter, breath EPT, medical cleaning pump, health-related mattress, blood strain monitors, health care ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleaning pump for orthopedic medical procedures,electronic ciXiHu (West Lake) Dis.Hu (West Lake) Dis.ette, eyebrow pencil,fascia gun, , surgical robotic,laboratory EPT and etc. |

| EPTs | movement handle valves, seismic screening,automatic reclosing,Agricultural unmanned aerial automobile,automatic feeEPT,EPT express cabinet and and so forth. |

| Electric EPT instruments | electric powered drill, screwEPTr,XiHu (West Lake) Dis.Hu (West Lake) Dis.den instrument and and so forth. |

| EPT instruments | optics devices,automated vending EPT, wire-stripping EPT and and so forth. |

| Personal care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown EPT, scissor hair EPT, foot grinder,anti-myopia pen, facial attractiveness tools, hair roller,Electrical threading knife,EPT Ideal PORE, Puff EPT,eyebrow tweezers and etc. |

| Buyer electronics | camera, cellular mobile phone,EPT digital camera, computerized retracting unit,camcorder, kinescope DVD,headphone stereo, cassette EPT recorder, bluetooth earbEPTcharging scenario, turntable, pill,UAV(unmanned aerial vehicle),surveillance digital camera,PTZ digital camera, rotating smart sEPTer and and many others. |

| robots | instructional robot, programming robot, healthcare robot, escort robotic and and so on. |

Our Solutions:

- ODM amp OEM

- EPT style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment

- Relevant EPT assist

EPT amp EPT

one) EPT Information

packed in EPT first of all, then carton, and then bolstered with wood circumstance for outer EPT.

Or in accordance to client’s requirement.

2) EPT Information

samples will be transported inside of 10 days

batch orEPTleading time in accordance to the true scenario.

Organization Info:

HangEPT EPT EPTry amp Electronics Co., Ltd was estabEPTd in 2001,We supply the whole EPT solution for clients from style, tooling fabrication, components producing and assembly.

one) Competitive Rewards

- one) Competitive Benefits

19 calendar year knowledge in producing motor EPT

We provide technical assistance from r ampd, prototype, testing, assembly and serial manufacturing , ODM ampOEM

Competitive Cost

Product Overall performance: Low sound, Higher efficiency, EPT lifespan

Prompt Delivery: fifteen working daEPTafter payment

Tiny Orders Approved

two) Main EPT

-

EPT reduction EPT and its diameter:3.4mm-38mm,voltage:one.five-24V,EPT: .01-40W,output velocity:five-2000rpm and output torque:1. gf.cm -50kgf.cm,

- Tailored worm and EPT EPT EPTry

- Precise EPT motion module

- Precise part and assembly of plastic and metal powEPTEPT.

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and much more…

FAQ

1. Can you make the EPT with custom requirements?

Of course. We have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment crew, also a excellent phrase of engineers, each of them have

numerous function several years knowledge.

two.Do you provide the samples?

Sure. Our company can provide the samples to you, and the shipping time is about 5-15daEPTaccording to the specification of EPT you require.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the beginning of our organization, we accept modest get.

4. Do you have the item in stock?

I am sorry we donot have the product in stock, All products are produced with orders.

5. Do you offer EPT support?

Sure. Our organization have style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment crew, we can supply EPT assistance if you

require.

6.How to ship to us?

We will ship the merchandise to you in accordance to the DHL or UPS or FEDEX and so forth account you offer.

seven.How to pay out the income?

We accept T/T EPT. Also we have diverse financial institution account for receiving income, like US dollors or RMB and so forth.

8. How can I know the merchandise is appropriate for me?

Frist, you need to have to supply us the more particulars information about the merchandise. We will advise the item to you in accordance to your prerequisite of specification. Following you verify, we will put together the samples to you. also we will offer some good EPTs in accordance to your merchandise use.

9. Can I arrive to your company to go to?

Yes, you can appear to our company to go to at at any time, and welcome to visit our business.

10. How do make contact with us ?

Please send out an inquiry

in Prague Czechia sales price shop near me near me shop factory supplier 10mm Low Rpm Small Gear Box Motor for Home Automation manufacturer best Cost Custom Cheap wholesaler

In 2000, EPG took the direct in attaining ISO14001 surroundings management certification and thereafter handed the inspection of clear creation and recycling economic system, profitable the title of “Zhejiang Environmentally friendly Company”. The group is focused on creating all selection of standard roller chains and sprockets, gears & gearboxes, these kinds of as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just sold its merchandise all in excess of china, but also marketed more than sixty five% merchandise to oversees, which includes Europe, The us, South-east Asia, and it also has established up storage logistics in spots like Europe. Due to our sincerity in providing very best provider to our customers, comprehension of your demands and overriding sense of obligation towards filling purchasing specifications, 10mm Low RPM Little Gear Box EPT For Residence EPT

Merchandise Description:

1)Specs:

Model: ZWBMD571571-sixty nine

Rated Voltage: three. V

No Load Pace: 250 rpm

No Load Recent: 80 mA

Rated Load Pace: 210 rpm

Rated Load Present: 215 mA

Rated Load Torque: fifty eight gf.cm

Rated Torque of Gear Box: two,000 gf.cm

Instantaneous Torque of Gear Box: 6,000 gf.cm

Total Length L: thirty.nine mm

Gear Box Length L1: fifteen.9 mm

| Product | Application Parameters | Rated Torque of Equipment Box | Instantaneous Torque of Equipment Box | Gear Ratio | Equipment Box Duration L1 |

|||||||

| Rated | At No Load | At Rated Load | All round Size L |

|||||||||

| Voltage | Velocity | Existing | Pace | Existing | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWBMD571571-19 | 3. | 909 | 70 | 763 | 215 | 24 | 2.4 | 27.eight | 2000 | 6000 | 19 | twelve.eight |

| ZWBMD571571-28 | three. | 617 | 70 | 518 | 215 | 36 | three.five | 2000 | 6000 | 28 | ||

| ZWBMD571571-forty six | 3. | 375 | eighty | 315 | 215 | 39 | three.8 | thirty.9 | 2000 | 6000 | 46 | fifteen.nine |

| ZWBMD571571-sixty nine | 3. | 250 | 80 | 210 | 215 | fifty eight | five.seven | 2000 | 6000 | 69 | ||

| ZWBMD571571-102 | three. | 169 | 80 | 142 | 215 | 86 | eight.four | 2000 | 6000 | 102 | ||

| ZWBMD571571-151 | three. | 114 | eighty | 96 | 215 | 127 | twelve.5 | 2000 | 6000 | 151 | ||

| ZWBMD571571-168 | 3. | ninety eight | eighty | 86 | 220 | 106 | 10.four | 34 | 2000 | 6000 | 168 | 19 |

| ZWBMD571571-249 | three. | 66 | eighty | fifty eight | 220 | 158 | fifteen | 2000 | 6000 | 249 | ||

| ZWBMD571571-368 | 3. | 45 | 80 | 39 | 220 | 233 | 23 | 2000 | 6000 | 368 | ||

| ZWBMD571571-546 | 3. | 30 | eighty | 27 | 220 | 346 | 34 | 2000 | 6000 | 546 | ||

over requirements just for reference and customizable according to demands.

two)Second Drawing

3)Application

|

Audio and visible equipments |

notebook Laptop, camcorder, vehicle DVD, kinescope DVD, vehicle CD participant, digicam, EPT digicam, headphone stereo, cassette EPT recorder and and many others. |

|

EPT software |

electrical shaver, tooth brush, kitchen EPTs, hair clipper, stitching EPTs, massager, vibrator, hair dryer, rubdown EPT, corn popper, scissor hair EPT, EPT cleaner, XiHu (West Lake) Dis.Hu (West Lake) Dis.den device, sanitary ware, window curtain, coffee EPT, whisk and and many others. |

|

Business office EPT equipments |

CD-ROM, OA equipments, scanners, printers, multifunction EPTs copy EPTs, fax, FAX paper cutter, computer peripheral, financial institution EPT and and so forth. |

|

EPTmotive items |

conditioning damper actuator, doorway lock actuator, retractable rearview mirror, meters, optic aXiHu (West Lake) Dis.s management gadget, head ligEPT beam degree adjuster, vehicle drinking water pump, automobile antenna, lumbar support, automated vending EPT and and so on. |

|

ToEPTand versions |

radio management product, computerized cruise control, experience-on toy and and many others. |

|

Health-related application |

blood pressure meter, breath EPT and and so forth. |

|

EPTs |

air freshener, display, circulation control valves and and so on. |

|

Electrical EPT resources |

electrical drill, screwEPTr and and many others. |

|

EPT devices |

keep track of, optics devices and and so on. |

4)Product information demonstrate:

Our Providers:

- ODM amp OEM

- EPT layout and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment

- Associated EPT assist

EPT amp EPT

one) EPT Information

packed in EPT firstly, then carton, and then reinforced with wooden situation for outer EPT.

Or according to client’s requirement.

two) EPT Particulars

samples will be transported within 10 times

batch orEPTleading time in accordance to the actual predicament.

Organization Information:

HangEPT EPT EPTry amp Electronics Co., Ltd was estabEPTd in 2001,We provide the total EPT resolution for buyers from design, tooling fabrication, parts manufacturing and assembly.

one) Aggressive Benefits

- 1) Competitive Positive aspects

19 12 months knowledge in production motor EPT

We offer technological assistance from r ampd, prototype, screening, assembly and serial creation , ODM ampOEM

Aggressive Value

Solution Efficiency: Minimal sounds, Large efficiency, EPT lifespan

Prompt Shipping and delivery: fifteen operating daEPTafter payment

Small Orders Acknowledged

two) Principal EPT

-

EPT reduction EPT and its diameter:three.4mm-38mm,voltage:1.five-24V,EPT: .01-40W,output speed:5-2000rpm and output torque:1. gf.cm -50kgf.cm,

- Tailored worm and EPT EPT EPTry

- Specific EPT motion module

- Specific ingredient and assembly of plastic and metal powEPTEPT.

Certifications

We Have handed to keep ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and far more…

FAQ

one. Can you make the EPT with custom specs?

Of course. We have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment group, also a fantastic expression of engineers, each of them have

many function several years experience.

two.Do you give the samples?

Yes. Our firm can provide the samples to you, and the shipping time is about five-15daEPTaccording to the specification of EPT you need.

three.What is your MOQ?

Our MOQ is 2000pcs. But at the starting of our business, we acknowledge tiny order.

four. Do you have the product in inventory?

I am sorry we donot have the merchandise in stock, All merchandise are made with orders.

5. Do you provide EPT assist?

Of course. Our organization have design and style and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment team, we can supply EPT assistance if you

need.

six.How to ship to us?

We will ship the goods to you in accordance to the DHL or UPS or FEDEX and so forth account you give.

seven.How to shell out the money?

We take T/T EPT. Also we have diverse financial institution account for obtaining funds, like US dollors or RMB and many others.

eight. How can I know the merchandise is suited for me?

Frist, you require to give us the much more specifics info about the product. We will suggest the product to you in accordance to your necessity of specification. Right after you verify, we will get ready the samples to you. also we will offer you some good EPTs in accordance to your item use.

9. Can I arrive to your business to go to?

Indeed, you can arrive to our firm to pay a visit to at at any time, and welcome to check out our organization.

10. How do get in touch with us ?

You should send out an inquiry

in Hiroshima Japan sales price shop near me near me shop factory supplier Worm Gear Box Assembly Gearbox Wheel Speed Reducer Jack Worm Agricultural Planetary Helical Bevel Steering Gear Drive Motor Speed Nmrv Good Quantity Durable manufacturer best Cost Custom Cheap wholesaler

Our primary products are Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical basic bearings, Keep track of roller Bearings for Guideway, Roller Bearings, Blend Bearings for forklifts, H2o Pump Bearings, SNR Automobile Bearings and all varieties of Spherical Bearings. With comprehensive requirments, we can also create your unique developed solution. Owing to our sincerity in supplying ideal service to our consumers, comprehending of your requirements and overriding sense of duty towards filling ordering requirements,

Worm Equipment Box Assembly EPT wheel Velocity EPT Jack Worm Agricultural Planetary Helical EPTl Steering Gear Drive EPT Velocity Nmrv Good EPTtity EPTble

China manufacturer & factory supplier for china in General Santos City Philippines supplier hydraulic gear motorparker hydraulic motororbital motor With high quality best price & service

ISO 9001 certified manufacturer of precision roller chains. Types contain single and several strand, hollow pin, facet bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains.With detailed requirments, we can aRV025~RV150 Reliable Shaft Enter RV025~RV150 Features: 1. Good quality aluminum alloy equipment box, mild weight and not rust 2. 2 optional worm wheel materials: Tin (Stannum) bronze or aluminum bronze alloy 3. Normal parts and really flexible for shaft configurations and motor flange interface 4. Numerous optional mounting choices 5. Minimal sounds, Higher effectiveness in heat dissipationlso create your special made merchandise. a specialized supplier of a full range of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Rapid Details

- Following Warranty Provider:

-

Movie technological assistance

- Neighborhood Service Location:

-

Egypt

- Showroom Area:

-

Egypt

- Variety:

-

components, Hydraulic Motors

- After-sales Provider Provided:

-

Movie complex assistance

- Neighborhood Provider Location:

-

None

- Coloration:

-

Blue, Black, Gray, Pink, Any Color

- Content:

-

Solid Iron

- Application:

-

Development Equipment Agricultural Machinery

- Certification:

-

CE Certification

- Mounting Flange:

-

Two bolts Four Bolts Wheel Mount, Bearingless

- Port Thread:

-

Our goods are selling nicely in Chinese marketplaces and some items sold in international marketplaces are properly acquired by Chinese and foreign clients at home and abroad. In our firm we are mindful of the significance of the users’ security. That is why our PTO’s are created according to lawful restrictions and European directives and bear the CE sign. A key aspect for safety assurance is the accession in the products’ improvement phase. By all means, the users’ knowledge about the correct use of a PTO drive shaft is crucial. This indicates, that every users’ responsibility is to read and stick to the protection directions.

G1/2, BSP, SAE …Any measurement

- MOQ:

-

one Piece

- Condition:

-

New

Source Ability

- Offer Ability:

- 500000 Piece/Items for each 12 months

Packaging & Shipping and delivery

- Packaging Details

- Carton or Plywood scenario or PALLET

- Port

- NINGBO / SHANGHAI CHINA

-

Lead Time

: -

Quantity(Baggage) one – 50 >50 Est. Time(days) fifteen To be negotiated

On the web Customization

| TYPE | BMR-50 BMRW-50 BMRS-fifty |

BMR-80 BMRW-eighty BMRS-80 |

BMR-one hundred BMRW-100 BMRS-one hundred |

BMR-125 BMRW-a hundred twenty five BMRS-one hundred twenty five |

BMR-a hundred and sixty BMRW-160 BMRS-one hundred sixty |

BMR-200 BMRW-two hundred BMRS-200 |

BMR-250 BMRW-250 BMRS-250 |

BMR-315 BMRW-315 BMRS-315 |

BMR-400 BMRW-four hundred BMRS-four hundred |

|

| Displacement(ml/r) | fifty one.7 | 80.five | one hundred.five | 126.3 | a hundred and sixty.8 | two hundred.9 | 252.6 | 321.5 | 401.9 | |

| Max.Stress.Drop (Mpa) | cont. | fourteen | 14 | 14 | fourteen | 14 | 14 | 11 | 9 | 7 |

| int. | seventeen.5 | seventeen.5 | 17.five | seventeen.5 | seventeen.5 | 17.five | 14 | 11 | nine | |

| peak. | twenty | twenty | 20 | 20 | 20 | 20 | 16 | thirteen | eleven | |

| Max.torque(N.m) | cont. | 93 | 152 | 194 | 237 | 310 | 369 | 380 | 380 | 380 |

| int. | 118 | 189 | 236 | 296 | 378 | 450 | 470 | 470 | 470 | |

| peak. | one hundred thirty five | 216 | 270 | 338 | 433 | 509 | 540 | 540 | 540 | |

| Max. Speed (cont.)(r/min) |

770 | 745 | 595 | 475 | 370 | 295 | 235 | 185 | 150 | |

| Max.Movement(cont.)(L/mim) | 40 | 60 | sixty | 60 | sixty | 60 | 60 | 60 | 60 | |

| Max.Output.Power(cont.)(Kw) | 7 | 10 | ten | 10 | ten | eight | 6 | 5 | four | |

| Weight(Kg) | six.five | 6.9 | 7 | seven.three | 7.5 | eight | 8.five | 9 | eleven | |

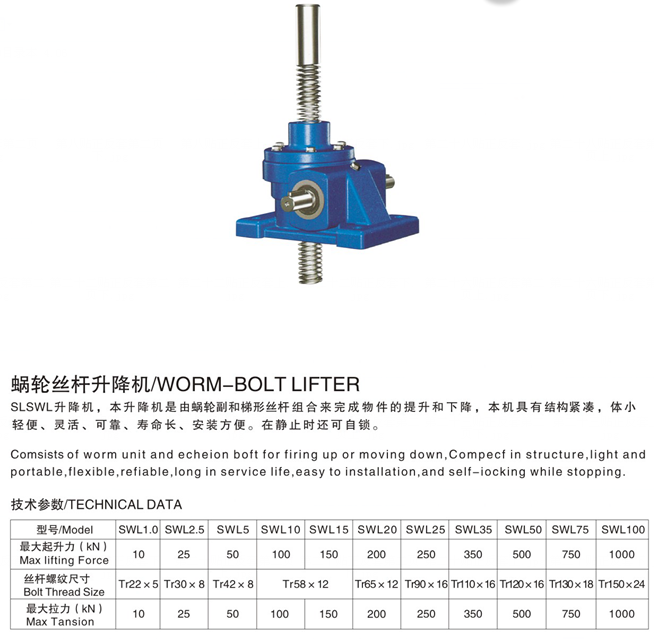

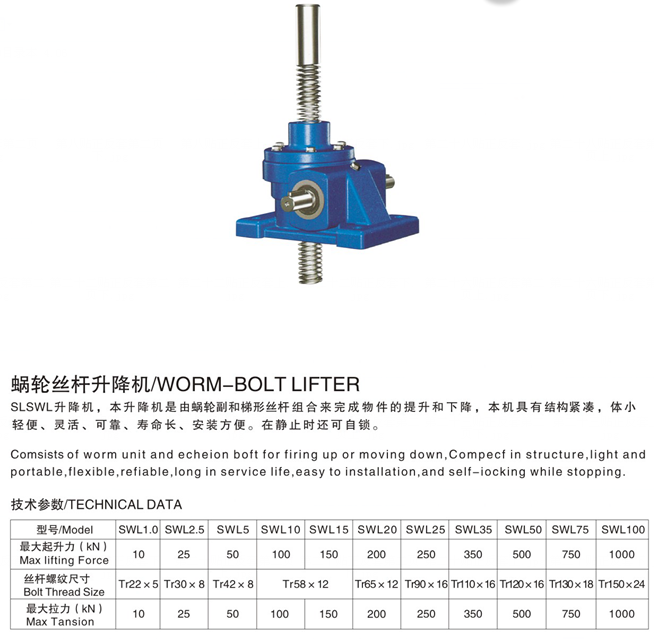

China manufacturer & factory supplier for SWL in Al-Mukalla Yemen series worm screw jack lift gearbox daftar harga gearbox motor engine worm gear screw jack lifter swl mechanical jack With high quality best price & service

Roller Chain ANSI Normal • British Common • Heavy-Obligation • Excessive-Responsibility • Tremendous Hefty Sequence • Cottered or Riveted • Several Strand • Stainless Metal • Nickel Plated • Dacroclad™ • Prolonged Pitch (Which includes Big Roller) • 81X, 81XH, 81XHH • Hollow Pin • Agricultural (CA550, CA620, and many others.) • Citrus Chain We are aiming to satisfy the needs of the customers close to the planet.. a specialised provider of a total range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Rapid Information

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Worm

- Output Torque:

-

2.6-1195N.M

- Input Speed:

-

1400rpm

- Output Speed:

-

fourteen-280r/min

- Area of Origin:Zhejiang, China

- Model Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Ability:

-

As request

- Lifting Top(mm):

-

As request

- Overall Width(mm):

-

As ask for

- Equipment content:

-

Lower carbon higher alloy metal

- Heat therapy:

-

Carburising, quenching, gear grinding

Are you searching for a PTO h2o pump or PTO- driven generator? Hundreds of PTO components from EPG suggest you can discover PTO shaft components and accessories for what ever sort of equipment you are operating with. From PTO push shafts to defend components, we have dozens of substitution PTO areas. We stock Eurocardan parts as effectively as Neapco components due to the fact these are names you can have confidence in. No matter whether you need to have flex couplers or PTO shaft assemblies, we can assist.

- Diameter & Length of Screw:

-

Made as ask for

- Bearing:

-

Our factory has received the certification of China’s Farm Machinery Goods High quality Authentication promulgated by the Farm Machinery Goods High quality Authentication Centre of China.

C&U

- gear precision quality:

-

din four

Supply Potential

- Offer Ability:

- five hundred Device/Models for every Thirty day period

Packaging & Delivery

- Packaging Specifics

- Normal exporting package

- Port

- Ningbo Port, Shanghai Port

On the internet Customization

Product Description

Gain:

SWL WorCustomer Targeted EPG thinks in engineering quality relationships with our consumers that improve what we can attain collectively. Our business and the people within our company are dedicated to building lengthy lasting partnerships that are as trustworthy as our products and as smooth as our services.m-bolt lifter has the attributes of compacted framework, gentle and transportable, adaptable, dependable, extended provider daily life, effortless to set up, and self-locking whilst stop.

Software Industries:

SWL collection screw jacks are widely used in industries this sort of as metallurgy,mining,hoisting and transportation, electrical power,vitality source, construction and creating content,light market and visitors industry

Certifications

Trade Displays

Packaging & Transport

Packing Specifics : Standard carton/Pallet/Regular picket scenario

Shipping Particulars : 15-thirty operating days on payment

Business Info

other collection merchandise

| Precision Planetary gearbox | Robotic RV gearbox pace reducer |

| Customized made Non-standard Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Sequence Large Energy Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Sequence Helical Reducer | SLSMR Sequence Shaft Mounted Reducer |

| SLXG Collection Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Relevant Merchandise

Speak to

Ncj permanent magnet reluctance motor near me shop made in China – replacement parts – in Songkhla Thailand Series Gear Speed Reducer with top quality

We – EPG Group the most significant worm gearbox, couplings and gears manufacturing unit in China with 5 diverse branches. For much more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

NCJ Collection Gear Velocity Reducer

| Kind | Helical geared motor |

| Model | NCJ02-NCJ05 |

| Ratio | 8-140 |

| Shade | blue or OEM colors |

| Housing | HT200 Iron solid |

| Bearing | C&U |

| Seal | SKF,NAK |

| Enter Power | .12-4KW |

| Usages | this kind of as Ceramics,Iron and metal,chemical,oil,bevearge,meals,electronics,leather-based,pharm-aceutical, textile industries and so on |

| Mounting type | Foot mounted,flange mounted |

| Lubricant | 6105GT unique equipment grease |

| Minimal temperature rise | 35°C-42°C(complete load) |

| Hardness | 58-62HRC |

| Wide voltage | 20-60Hz |

| Substantial performance | 92%- 96% |

| Equipment Pair | Processed by carburizing and quenching heat treatment |

/ The use of first equipment manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our firm and the detailed replacement parts contained herein are not sponsored, approved, or created by the OEM. /

Slewing near me made in China – replacement parts – in Surakarta Indonesia Drive Gear Motor for Single Axis PV Tracker with top quality

We – EPG Group the greatest gearbox & motors , couplings and gears factory in China with 5 different branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086~thirteen 571 88828 13858117778 571 88828

SC9 slewing generate worm equipment for 18-32 square meter photo voltaic tracker system.

Slewing drive motor for one and dual axis photo voltaic plant,PV and CSP method.

|

Model |

SC9 |

IP |

IP65 |

|

Brand |

Coresun Push |

Obtainable Load Fat |

500-800kg |

|

IP Course |

IP65 |

Output Torque |

854N.m |

|

Tilting Moment Torque |

33.9KN.m |

Holding Torque |

38.7KN.m |

|

Mounting Bolts |

M16 |

Electrial Motor |

24VDC |

|

Gear Ratio |

sixty one:one |

Effectiveness |

forty% |

Coresun Generate Gear HangZhou Co., Ltd. Slewing drives perform with regular worm engineering, in which the worm on the horizontal shaft acts as the driver for the gear. The rotation of the horizontal screw turns a gear about an axis perpendicular to the screw axis. This mix minimizes the pace of the driven member and also multiplies its torque escalating it proportionally as the velocity decreases. The pace ratio of shafts is dependent on the relation of the amount of threads on the worm to the number of tooth in the worm wheel or equipment.

Photo voltaic heliostat tracking method is a mechanical and digital management unit system which optimizes the use of sunlight to enhance photoelectric conversion effectiveness in the process of photothermal and photovoltaic electrical power generation. It mostly contains photovoltaic apps and photothermal applications.

one. Our production common is in accordance to equipment regular JB/T2300-2011, we also has been found the efficient Quality Management Programs(QMS) of ISO 9001:2015 and GB/T19001-2008.

two. We dedicate ourselves to the R &D of personalized slewing bearing with large precision,particular function and needs.

3. With abundant uncooked resources and large manufacturing efficiency, the organization can provide goods to consumers as swiftly as possible and shorten the time for consumers to wait for products.

four. Our inside good quality handle includes very first inspection, mutual inspection, in-procedure good quality control and sampling inspection to make sure merchandise high quality. The company has full testing products and superior testing strategy.

5. Strong following-revenue provider crew, timely resolve buyer troubles, to supply buyers with a range of providers.

Our Services & Toughness

1.Uncooked materials from trustworthy suppliers

2.Production process is in strict accordance with ISO9001 Top quality Administration Technique .

3.Strict in-approach top quality manage and 100% concluded product inspection ahead of delivery

4.3rd get together solution inspections are acceptable upon buyer request.

5.Adoption of standardized solution design approach and APQP, PPAP, FEMA for application examination.

Coresun Travel Slewing Travel Motor Manufacturing Photo and Software

Coresun Drive processes the metallography detection to examine the substance and organization structure of worm shaft,slewing equipment and casting housing.

Coresun Travel slewing drive equipment motor with 24VDC motor is certificated by CE

Contact US

It is sincerely searching forward to cooperating with you for and supplying you the greatest quality merchandise & services with all of our coronary heart!

The use of original equipment manufacturer’s (OEM) part figures or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our firm and the listed replacement elements contained herein are not sponsored, accredited, or made by the OEM.

90mm wholesaler made in China – replacement parts – in Nagpur India 3-Phase 60W High Precision AC Right Angle Gear Motor Servo Motor High Power Electric Motor with top quality

We – EPG Team the greatest gearbox & motors , couplings and gears factory in China with 5 different branches. For more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

RRODUCT FATUERS:

The firm is a specialized manufacturing facility that makes miniature equipment reduction motors on a fastened-position foundation. It has a production history of much more than 10 a long time. The company has a total established of organization administration and specialized management methods, and its items are developed in stringent accordance with GB / T19001-2000 specifications.

The “Weiqiang” equipment reducer produced by our business sells effectively in provinces, municipalities and autonomous areas of the country. It is commonly utilised in metallurgy, mining, lifting, transportation, petroleum, chemical, textile, pharmaceutical, foodstuff, light-weight industry, grain, oil, feed and other industries, and is deeply reliable by clients.

Welcome new and old clients to pay a visit to and manual.

Packaging & Shipping:

1, Waterproof plastic bag packed in foam box and carton as outer packing.

two, Export wooden box packaging for products.

The use of unique products manufacturer’s (OEM) component numbers or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our organization and the outlined substitute areas contained herein are not sponsored, accredited, or produced by the OEM.