Product Description

Company Profile

Established in 2009, HangZhou CZPT Trading Co., Ltd is a professional supplier for conveyor parts, located in ZHangZhoug province. We focus on supplying a variety of conveyor parts, including conveyor tubes, conveyor frames, conveyor rollers, bearing housings and so forth.

With our professional technology R&D team, and experienced quality control department, our products have been awarded the ISO9001 Quality Management System Standard and our main markets are in America, Europe, Asia and Australia.

|

Factory advantage |

Professional and experienced technology team | ||

| All products inspected before shipping with reasonable prices | |||

| Low MOQ and free sample | |||

| We are audited by SGS and passed the ISO9001:2008 certification | |||

|

Industries service |

Industrial machine | ||

| Electronic and communication | |||

| Oil, gas,mining and petroleum | |||

| Construction industry | |||

| Equipment | CNC Machining Center, CNC Lathes, CNC Milling Machines, Punching and drilling machines, Stamping machines | ||

| Precision Processing | CNC machining, CNC turning and milling, laser cutting, drilling, grinding, bending, stamping, welding | ||

Roller size

| No. | Standard Diameter | Length Range (mm) |

Bearing Type Min-Max |

Shell Thickness of Roller | |

| mm | Inch | ||||

| 1 | 63.5 | 2 1/2 | 150-3500 | 203 204 | 3.0mm-4.0mm |

| 2 | 76 | 3 | 150-3500 | 204 | 3.0mm-4.5mm |

| 3 | 89 | 3 1/3 | 150-3500 | 204 205 | 3.0mm-4.5mm |

| 4 | 102 | 4 | 150-3500 | 3.2mm-4.5mm | |

| 5 | 108 | 4 1/4 | 150-3500 | 306 | 3.5mm-4.5mm |

| 6 | 114 | 4 1/2 | 150-3500 | 306 | 3.5mm-4.5mm |

| 7 | 127 | 5 | 150-3500 | 306 | 3.5mm-5.0mm |

| 8 | 133 | 5 1/4 | 150-3500 | 305 306 | 3.5mm-5.0mm |

| 9 | 140 | 5 1/2 | 150-3500 | 306 307 | 3.5mm-5.0mm |

| 10 | 152 | 6 | 150-3500 | 4.0mm-5.0mm | |

| 11 | 159 | 6 1/4 | 150-3500 | 4.0mm-5.0mm | |

| 12 | 165 | 6 1/2 | 150-3500 | 307 308 | 4.5mm-6.0mm |

| 13 | 177.8 | 7 | 150-3500 | 309 | 4.5mm-6.0mm |

| 14 | 190.7 | 7 1/2 | 150-3500 | 309 310 | 4.5mm-7.0mm |

| 15 | 194 | 7 5/8 | 150-3500 | 309 310 | 4.5mm-8.0mm |

| 16 | 219 | 8 5/8 | 150-3500 | 4.5mm-8.0mm | |

Advantage:

1.The life time: More than 50000 hours

2. TIR (Total Indicator Runout)

0.5mm (0.0197″) for Roll Length 0-600mm

0.8mm (0.571″) for Roll Length 601-1350mm

1.0mm (0. 0571 “) for Roll Length over 1350mm

3.Shaft Float≤0.8mm

4..Samples for testing are available.

5. Lower resistance

6. Small maintain work

7. High load capability

8. Dust proof & water proof

CONVRYOR ROLLER SHAFTS

| We can produce roller shafts and We do customeized |

| Product Size:φ10mm – 70mm |

| Max Length: 3000mm |

| Surface Tolerance: g6 |

| Surface Roughness:0.8mm |

| Specification | ASTM A108 AS1443 |

| Steel Grade | Q235B,C1571,C1045(we can also do other steel grade per your requirments) |

| Size | Φ18mm-φ62mm |

| Diameter Tolerance | ISO286-2,H7/H8 |

| Straightness | 2000:1 |

| O.D | 63.5-219.1mm |

| W .T | 0.45-20mm |

| Length | 6–12m |

| Standard | SANS 657/3,ASTM 513,AS 1163,BS6323,EN10305 |

| Material | Q235B, S355,S230,C350,E235 etc. |

| Technique | Welded,Seamless |

| Surface | oiled ,galvanized or painted with all kinds of colors according to client’s request. |

| Ends | 1.Plain ends, |

| 2.Threading at both side with plastice caps | |

| 3.Threading at both side with socket/coupling. | |

| 4.Beveled ends, and so on | |

| Packing | 1.Water-proof plastic cloth, |

| 2.Woven bags, | |

| 3.PVC package, | |

| 4.Steel strips in bundles | |

| 5.As your requirment | |

| Usage | 1.For low pressure liquid delivery such as water,gas and oil. |

| 2.For construction | |

| 3.Mechanical equipment | |

| 4.For Furniture | |

| Payment&Trade Terms | 1.Payment : T/T,L/C, D/P, Western union |

| 2.Trade Terms:FOB/CFR/CIF | |

| 3.Minimum quantity of order : 10 MT (10,000KGS) | |

| Delivery Time | 1.Usually,within10-20days after receiving your down payment. |

| 2.According to the order quantity |

Conveyor Roller Tube

|

Conveyor Roller Tube |

Specification | SANS657/3,ASTM513,AS1163,BS6323,EN10305 or equivalent international standard. |

| Steel grade | S355/S230,C350,E235,Q235B | |

| Sizes | 63.5mm-219.1mm ect | |

| Ovality tolerance of body | ≤0.4mm(60.3mm-152.4mm) | |

| ≤0.5mm(159MM-168.3mm) | ||

| ≤0.6mm(178mm-219mm) | ||

| Straightness | 2000:1 |

if you are interesting in our products or want any further information, please feel free to contact us!

I am looking CZPT to your reply.

Best regards

Ruth

HangZhou CZPT TRADING CO., LTD

1801 CZPT Building, No.268 Xierhuan Road, HangZhou City, ZHangZhoug Province, China

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Steel Grade: | C1018 C1020 |

|---|---|

| Standard: | ASTM A108 |

| Size: | Od18mm—62mm |

| Surface Tolerance: | G6 |

| Max Length: | Max 3000mm |

| Surface Roughness: | 0.8 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of driveline configurations based on vehicle type?

Yes, there are different types of driveline configurations based on the type of vehicle. Driveline configurations vary depending on factors such as the vehicle’s propulsion system, drivetrain layout, and the number of driven wheels. Here’s a detailed explanation of the driveline configurations commonly found in different vehicle types:

1. Front-Wheel Drive (FWD):

In front-wheel drive vehicles, the driveline configuration involves the engine’s power being transmitted to the front wheels. The engine, transmission, and differential are typically integrated into a single unit called a transaxle, which is located at the front of the vehicle. This configuration simplifies the drivetrain layout, reduces weight, and improves fuel efficiency. Front-wheel drive is commonly found in passenger cars, compact cars, and some crossover SUVs.

2. Rear-Wheel Drive (RWD):

Rear-wheel drive vehicles have their driveline configuration where the engine’s power is transmitted to the rear wheels. In this setup, the engine is located at the front of the vehicle, and the drivetrain components, including the transmission and differential, are positioned at the rear. Rear-wheel drive provides better weight distribution, improved handling, and enhanced performance characteristics, making it popular in sports cars, luxury vehicles, and large trucks.

3. All-Wheel Drive (AWD) and Four-Wheel Drive (4WD):

All-wheel drive and four-wheel drive driveline configurations involve power being transmitted to all four wheels of the vehicle. These configurations provide better traction and handling in various driving conditions, particularly on slippery or off-road surfaces. AWD systems distribute power automatically between the front and rear wheels, while 4WD systems are often manually selectable and include a transfer case for shifting between 2WD and 4WD modes. AWD and 4WD configurations are commonly found in SUVs, crossovers, trucks, and off-road vehicles.

4. Front Engine, Rear-Wheel Drive (FR) and Rear Engine, Rear-Wheel Drive (RR):

In certain performance vehicles and sports cars, driveline configurations may involve a front engine with rear-wheel drive (FR) or a rear engine with rear-wheel drive (RR). FR configurations have the engine located at the front of the vehicle, transmitting power to the rear wheels. RR configurations have the engine located at the rear, driving the rear wheels. These configurations provide excellent balance, weight distribution, and handling characteristics, resulting in enhanced performance and driving dynamics.

5. Other Configurations:

There are also various specialized driveline configurations based on specific vehicle types and applications:

- Mid-Engine: Some high-performance sports cars and supercars feature a mid-engine configuration, where the engine is positioned between the front and rear axles. This configuration offers exceptional balance, handling, and weight distribution.

- Front-Engine, Front-Wheel Drive (FF): While less common, certain compact and economy cars employ a front-engine, front-wheel drive configuration. This layout simplifies packaging and interior space utilization.

- Part-Time 4WD: In certain off-road vehicles, there may be a part-time 4WD driveline configuration. These vehicles typically operate in 2WD mode but can engage 4WD when additional traction is needed.

These are some of the driveline configurations commonly found in different vehicle types. The choice of driveline configuration depends on factors such as the vehicle’s intended use, performance requirements, handling characteristics, and specific design considerations.

Can you provide real-world examples of vehicles and machinery that use drivelines?

Drivelines are used in a wide range of vehicles and machinery across various industries. These driveline systems are responsible for transmitting power from the engine or motor to the wheels or driven components. Here are some real-world examples of vehicles and machinery that utilize drivelines:

1. Automobiles:

Drivelines are integral to automobiles, providing power transmission from the engine to the wheels. Various driveline configurations are used, including:

- Front-Wheel Drive (FWD): Many compact cars and passenger vehicles employ front-wheel drive, where the driveline powers the front wheels.

- Rear-Wheel Drive (RWD): Rear-wheel drive is commonly found in sports cars, luxury vehicles, and trucks, with the driveline powering the rear wheels.

- All-Wheel Drive (AWD) and Four-Wheel Drive (4WD): AWD and 4WD drivelines distribute power to all four wheels, enhancing traction and stability. These systems are used in SUVs, off-road vehicles, and performance cars.

2. Trucks and Commercial Vehicles:

Trucks, including pickup trucks, delivery trucks, and heavy-duty commercial vehicles, rely on drivelines to transmit power to the wheels. These drivelines are designed to handle higher torque and load capacities, enabling efficient operation in various work environments.

3. Agricultural Machinery:

Farm equipment, such as tractors, combines, and harvesters, utilize drivelines to transfer power from the engine to agricultural implements and wheels. Drivelines in agricultural machinery are engineered to withstand demanding conditions and provide optimal power delivery for field operations.

4. Construction and Earthmoving Equipment:

Construction machinery, including excavators, bulldozers, loaders, and graders, employ drivelines to power their movement and hydraulic systems. Drivelines in this sector are designed to deliver high torque and endurance for heavy-duty operations in challenging terrains.

5. Off-Road and Recreational Vehicles:

Off-road vehicles, such as ATVs (All-Terrain Vehicles), UTVs (Utility Task Vehicles), and recreational vehicles like dune buggies and sand rails, rely on drivelines to provide power to the wheels. These drivelines are engineered to handle extreme conditions and offer enhanced traction for off-road adventures.

6. Railway Locomotives and Rolling Stock:

Drivelines are utilized in railway locomotives and rolling stock to transmit power from the engines to the wheels. These driveline systems are designed to efficiently transfer high torque and provide reliable propulsion for trains and other rail vehicles.

7. Marine Vessels:

Drivelines are employed in various types of marine vessels, including boats, yachts, and ships. They transmit power from the engines to the propellers or water jets, enabling propulsion through water. Marine drivelines are designed to operate in wet environments and withstand the corrosive effects of saltwater.

8. Industrial Machinery:

Industrial machinery, such as manufacturing equipment, conveyor systems, and material handling machines, often utilize drivelines for power transmission. These drivelines enable the movement of components, products, and materials within industrial settings.

9. Electric and Hybrid Vehicles:

Drivelines are a crucial component in electric vehicles (EVs) and hybrid vehicles (HVs). In these vehicles, the drivelines transmit power from electric motors or a combination of engines and motors to the wheels. Electric drivelines play a significant role in the efficiency and performance of EVs and HVs.

These are just a few examples of vehicles and machinery that utilize drivelines. Driveline systems are essential in a wide range of applications, enabling efficient power transmission and propulsion across various industries.

Can you explain the components of a typical driveline and their specific roles?

A typical driveline consists of several components that work together to transmit power from the engine or power source to the driven components, enabling motion and providing torque. Each component plays a specific role in the driveline system. Here’s an explanation of the key components of a typical driveline and their specific roles:

1. Engine: The engine is the power source of the driveline system. It converts fuel energy (such as gasoline or diesel) into mechanical power by the process of combustion. The engine generates rotational power, which is transferred to the driveline to initiate power transmission.

2. Transmission: The transmission is responsible for selecting the appropriate gear ratio and transmitting power from the engine to the driven components. It allows the driver or operator to control the speed and torque output of the driveline. In manual transmissions, the driver manually selects the gears, while in automatic transmissions, the gear shifts are controlled by the vehicle’s computer system.

3. Drive Shaft: The drive shaft, also known as a propeller shaft or prop shaft, is a tubular component that transmits rotational power from the transmission to the differential or the driven components. It typically consists of a hollow metal tube with universal joints at both ends to accommodate variations in driveline angles and allow for smooth power transfer.

4. Differential: The differential is a gearbox-like component that distributes power from the drive shaft to the wheels or driven axles while allowing them to rotate at different speeds, particularly during turns. It compensates for the difference in rotational speed between the inner and outer wheels in a turn, ensuring smooth and controlled operation of the driveline system.

5. Axles: Axles are shafts that connect the differential to the wheels. They transmit power from the differential to the wheels, allowing them to rotate and generate motion. In vehicles with independent suspension, each wheel typically has its own axle, while in solid axle configurations, a single axle connects both wheels on an axle assembly.

6. Clutch: In manual transmission systems, a clutch is employed to engage or disengage the engine’s power from the driveline. It allows the driver to smoothly engage the engine’s power to the transmission when shifting gears or coming to a stop. By disengaging the clutch, power transmission to the driveline is temporarily interrupted, enabling gear changes or vehicle stationary positions.

7. Torque Converter: Torque converters are used in automatic transmissions to transfer power from the engine to the transmission. They provide a fluid coupling between the engine and transmission, allowing for smooth power transmission and torque multiplication. The torque converter also provides a torque amplification effect, which helps in vehicle acceleration.

8. Universal Joints: Universal joints, also known as U-joints, are flexible couplings used in the driveline to accommodate variations in angles and misalignments between the components. They allow for the smooth transmission of power between the drive shaft and other components, compensating for changes in driveline angles during vehicle operation or suspension movement.

9. Constant Velocity Joints (CV Joints): CV joints are specialized joints used in some drivelines, particularly in front-wheel-drive and all-wheel-drive vehicles. They enable smooth power transmission while accommodating variations in angles and allowing the wheels to turn at different speeds. CV joints maintain a constant velocity during rotation, minimizing vibrations and power losses.

10. Transfer Case: A transfer case is a component found in four-wheel-drive and all-wheel-drive systems. It transfers power from the transmission to both the front and rear axles, allowing all wheels to receive power. The transfer case usually includes additional components such as a multi-speed gearbox and differential mechanisms to distribute power effectively to the axles.

These are the key components of a typical driveline and their specific roles. Each component is crucial in transferring power, enabling motion, and ensuring the smooth and efficient operation of vehicles and equipment.

editor by CX 2024-02-04

China Roller chain and sprocket manufacturer Shrink belt drive vs chain drive atv China in Havana Cuba Wrapping Machine for Packing Boxes Books Bottles with ce certificate top quality low price

We – EPG Team the largest Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches.

If you are interested in any of our merchandise or would like to discuss a possible order, make sure you really feel free to speak to us. EPG Owing to our sincerity in supplying very best service to our customers, comprehending of your requirements and overriding sense of responsibility towards filling purchasing specifications,a specialised provider of a entire variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….major manufacturer and supplier of ball bearings and energy transmission gear. Given that it is starting in 1992, EPG has grown into a single of the major suppliers in the market. Crucial aspects that have contributed to our development is our commitment to the fundamentals of innovative design and style, aggressive pricing, outstanding client support, and solution availability. engineering course chains & precision roller chains. One strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains. Description:

Beautiful equipment, Steady top quality, Protection,strength saving, patented items, domestic initiative, application to the POF PVC PP movie thermal shrink packaging impact is excellent.

Functions:

one.Visual appeal and knot layout in accordance with countrywide stHangZhourds, the fuselage uses fingerprint resistant sheet creation following spray treatment.

2.Control panel utilizing programming method, 12V DC input , button change , digital exhibit.

3. Transmission utilizing 24v DC Motor speed handle using variable frequency technologies -9 file adjustment.

four.The conveyor belt can be utilised wire mesh belt, chain roller, Teflon mesh belt 3.

five.Heating making use of 600W 220V much infrared quartz heating tube.

6.Temperature manage employing higher precision clever temperature handle method . up and down temperature impartial regulation.

7.Very hot air circulation making use of 220V 60W 2200 to the extended axis motor with wind wheel.

eight.The bracket can be disassembled , and the top of the bracket can be altered.

| L SEALER | FQL 450 A | SHRINK TUNNEL | BSN 4571C |

| VOLTAGE | 220/fifty-60HZ | VOLTAGE | 380v fifty-60HZ |

| Energy | one.35KW | Electricity | 9KW |

| AIR Force: | five-7 | TUNNEL Dimensions(L*W*H) | 1200*400x200mm |

| Capability | fifteen-30bags/min | Solution Dimensions(W*H) | 350x150mm |

| Item MAX SIZE L+H(H<150mm) | <500mm | EPT Pace | -15m/min |

| Merchandise MAX Size W+H(H<150mm) | < 400mm | Content | CHAIN, TEFLON |

| SEALING Size | 550*450mm | CONVEYING LOAD | 20kg max |

| Machine Dimensions (L*W*H) | 1650*800*1450mm | Device Measurement (L*W*H) | 1600x560x660mm |

| Fat | 300KG | Fat | 80kg |

| Application: | POF.PE, | Software: | PE.POF |

The use of original tools manufacturer’s (OEM) part numbers or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our firm and the shown substitution areas contained herein are not sponsored, approved, or made by the OEM.

Best China manufacturer & factory M1 in Sakarya Turkey Straight teeth engraving machine gear rack With high quality best price

The substantial precise CNC tools, this kind of as Gradual-feeding wire-minimize equipment, jig grinding machine and electric discharge equipment, ensures the best good quality precision of mould processing, with the higher effective and environmental safety acid rolling line being the largest uncooked materials changing gear in the subject in china The wildly use of computerized milling equipment, substantial-speed automatic feeding punch, substantial pace computerized rolling and assembling machine ensures the large quality and efficiency of parts and chain creating.

Overview

Fast Information

- Relevant Industries:

-

Manufacturing Plant

- Area of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Product identify:

-

RACK

Provide Ability

- Provide Capability:

- 100000 Piece/Items for each Working day

Packaging & Delivery

- Packaging Information

- normal sea deserving deal

- Port

- shanghai ,ningbo

Online Customization

Item Description

M1 Straight enamel engraving equipment gear rack

We exported gear rack in huge amount to Europe, America, Australia, Brazil, South Africa, Russia and many others. There is normal equipment rack available and also particular gear rack as for every your drawing or samples. Our equipment racks made by CNC devices

one) Our equipment rack is developed as per DIN standards by CNC machine

two) The pressure angle: 20°/fourteen.5°

three) Module: M0.4-M36/DP1-DP25

four) The optimum duration can be 3500mm

five) The content can be Q235, C45, SS304, SS316L, aluminum, copper, nylon and so on.

Our gear racks are employed for window equipment, engraving machine, lift machine, opener rack, CNC machine, automobile, industrial utilization so on.

| Amount(Parts) | 1 | >1 |

| Est. Time(times) | thirty | To be negotiated |

Primary Products

Firm Info

Hangzhou At any time-Electrical power Industry Co., Ltd. is a specialized provider of a full variety of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined components and so on.

Because of to our sincerity in giving ideal services to our clientele, comprehending of your requirements and overriding perception of duty toward filling purchasing requirements, we have attained the have confidence in of purchasers around the world. Obtaining accrued valuable encounter in cooperating with foreign customers, our goods are selling effectively in the American, European, South American and Asian markets.Our goods are created by modern computerized equipment and tools. In the meantime, our items are manufactured according to higher top quality specifications, and complying with the worldwide superior standard requirements.

With many years’ knowledge in this line, we will be trusted by our positive aspects in competitive price tag, one-time supply, prompt response, on-hand engineering suShear bolt torque limiter (SB) EPG Group delivers large good quality PTO shafts with tubes mounted by spring pin, cross joints with roller bearings with rollerspport and good after-sales solutions.

Furthermore, all our generation processes are in compliance with ISO9001 expectations. We also can design and make non-common items to meet customers’ special demands. Good quality and credit score are the bases that make a company alive. We will offer best services and substantial quality products with all sincerity. If you need any info or samples, you should speak to us and you will have our before long reply.

Packaging & Shipping and delivery

Exhibition

Get in touch with Us

Our company has reliable financial power, builds up a technician staff contingent with large top quality, possesses the productionEPG develops and makes mechanical and mechatronic servo generate systems for sectors that require optimum precision. Our items consistently raise the bar close to the planet. assembly line of technicalization in China and perfect method examining on item quality and operates marketing networks through the region.

Best China manufacturer & factory china in Vladivostok Russian Federation supplier PE 400*600 small stone jaw crusher machine price with specifications for sale With high quality best price

Our technicians and engineers have 23 years of Experience in the Bearing Industry.

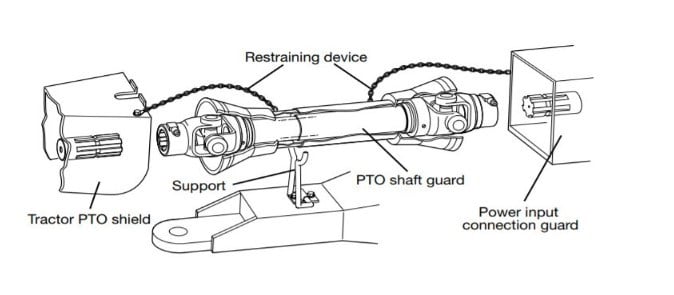

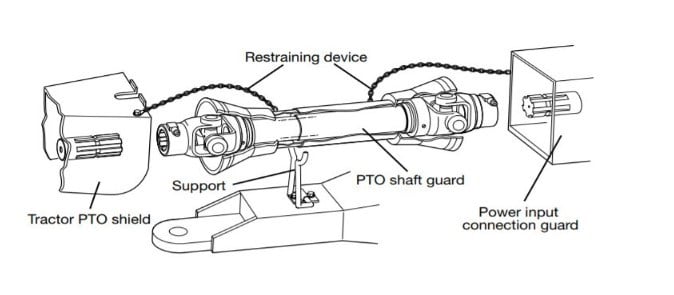

How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.

Overview

Quick Details

- Applicable IndustrIt was born in 1997, and is the fruit of the merger of different gearboxes brands. From the first products, it inherited a philosophy based in quality, profitability and technical rigor. EPG is present in all european market, through a complete distribution chain consisting of each market’s principal actors.ies:

-

Manufacturing Plant

- Color:

-

Orange Yellow White

- Max feeding size:

-

125 mm

- Speed:

-

250 rpm

- Model:

-

PE 400*600

Supply Ability

- Supply Ability:

- 20000 Set/Sets per Year small stone jaw crusher machine price with specifications for sa

Packaging & Delivery

-

Under the guidance of managerial sense of “Serving agriculture, scoring a success through quality of products and honesty in business”, our products have been trusted by clients and have gained a larger share of market.

- Packaging Details

- sea worthy case for PE 400*600 small stone jaw crusher machine price with specifications for sale

- Port

- Qingdao

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) 20 To be negotiated

Online Customization

Product Description

Small Stone Jaw Crusher Machine

Introduction

Jaw crusher machine has been widely used in metallurgy, chemicals, building materials, electricity, transportation, etc.Jaw crusher withsimple construction, robustness, reliable workability, easy maintenance and overhaul, and relatively low production and construction costs Industrial sector. It wasused to crush the compressive strength of 147 ~ 245MPa various ores and rocks of coarse, medium and fine crushing. In recent years, jaw crushermainlyfor metallurgy, mining, construction and other industrial sectors crushing high-strength, high hardness of the needs of micro-carbon ferrochrome.

Application:

Jaw crusher is mainly for medium-sized crushing of various ore and bulk materials,widely used in mining, metallurgy, building materials, roads, railways, water conservancy and chemical industries.Thehigh compressive strength of Crushed material is around 320MPa.

Specification

Performance characteristics:

1.Manufacturing process, select high-quality production materials.

2.Movable jaw assembly, to make it durable. Movable jaw assembly using high-quality steel castings, anddrivingthrough two large cast steel flywheel. In addition, the heavy eccentric shaft is also applied processing forging, all of which make the jaw crusher reliability.

3.The bearing blockusing cast steel structure. The integral steel housings ensure perfect fit with the crushing frame and also enhance the radial strength of the housings, which are not the benefits of split housings.

4.Using finite element analysis technology, crusher has high strength.

5.The crushing chamberusingsymmetrical “V” -shaped structure,so thatthewidth ofactual feed port and nominal feed portcan be consistent.

6.The adjust ofdischarge portismore efficient and convenient. The jaw crusher is equipped with a wedge block adjustment devicewhich make itsimpler, safer and faster to adjust than older pads.

7.Using largerbearing, high carrying capacity. Jaw crusher is equipped with more than the same specifications crusher durable eccentric shaft bearings, its higher carrying capacity and effective labyrinth seal to extend the service life of bearings.

8.Using tooth guard, increasing the effective length of the jaw, high yield. stone crusher machine price with resonable price.

PE 400*600 small stone jaw crusher machine price with specifications for sale:

| Type | Jaw Crusher |

| Brand | Tianqi |

| Model | PE |

| Capicity | 1-2200t/h |

| Warranty | 1 year |

Packaging & Shipping

Company Information

Founded in 1995, HangZhou Ever-Power machinery Co.,Ltd has 22 years of production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

Best China manufacturer & factory Elht in Irkutsk Russian Federation Series High Precision Harmonic Robot Reducer Drive Strain Wave Gear Set for CNC Machine Sewing Machine Small Gear Speed Ste With high quality best price

With many years’ experience in these lines, we have been distinguished from other suppliers in China by our advantages in competitive pricing, on-time delivery, prompt responses, on-hand engineering support and good after-sales services.

Overview

EPG is willing to cooperate sincerely and develop commonly with friends!

Quick Details

- Applicable Industries:

-

Hotels, Manufacturing Plant, Machinery Repair Shops, Retail

- Gearing Arrangement:

-

Helical

- Output Torque:

-

26-4200N.m

- Input Speed:

-

600-3000r/min

- Output Speed:

-

0.06-185r/min

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Black

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 300 >300 Est. Time(days) 30 To be negotiated

Online CustMaintenance Maintenance on these units is straight forward and like all moving parts these need their fair share of grease and should be greased regularly as these components work very hard and are subject to all that nature can provide for wear and tear. Good grease is essential here; put grease in until you see the old grease oozing out. Go easy on the “U” joints so you don’t blow the seals. Short bursts of a low pressured air grease gun or even better a hand pump gun will do the job and should be done based on hourly use. At least once a season the primary and secondary shafts should be separated. All debris and any rust should be cleaned off. Examine thoroughly for any signs of stress and apply a liberal amount of grease. In addition to this, both the PTO yoke holes need grease inside of them at least once a year along with the yoke lock pin.omization

Video Description

Products Description

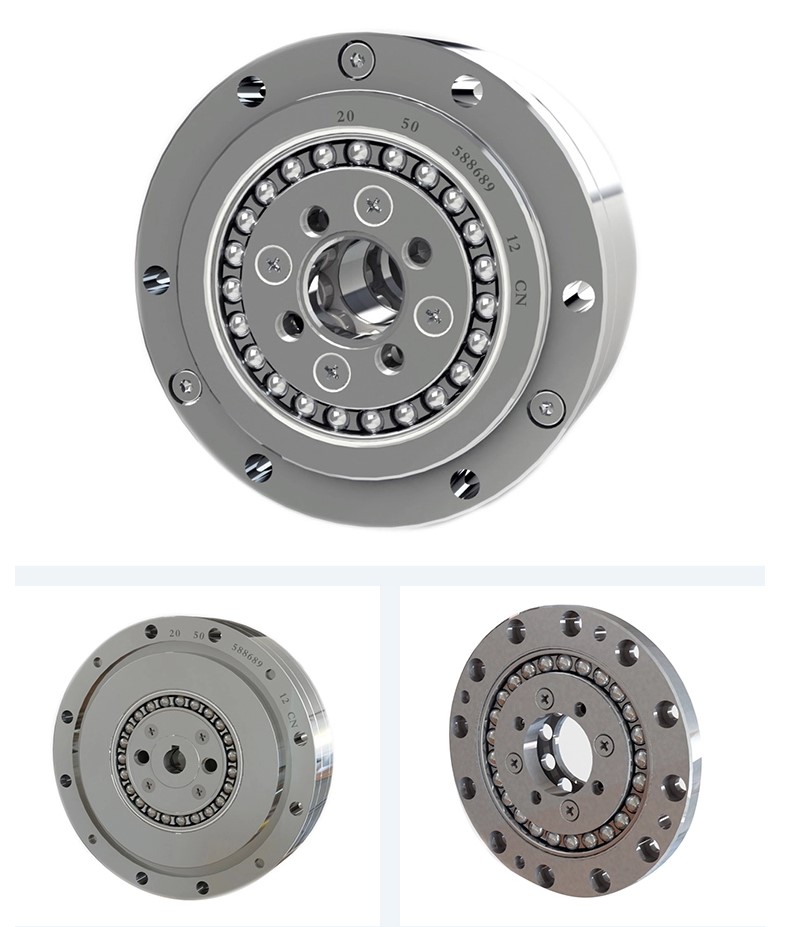

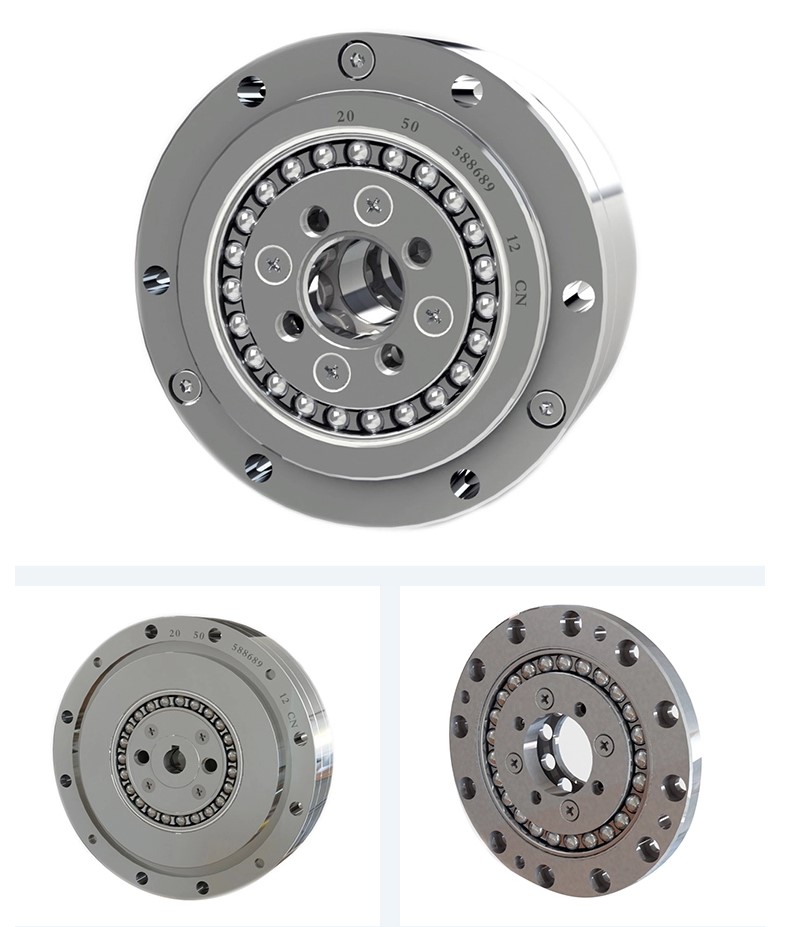

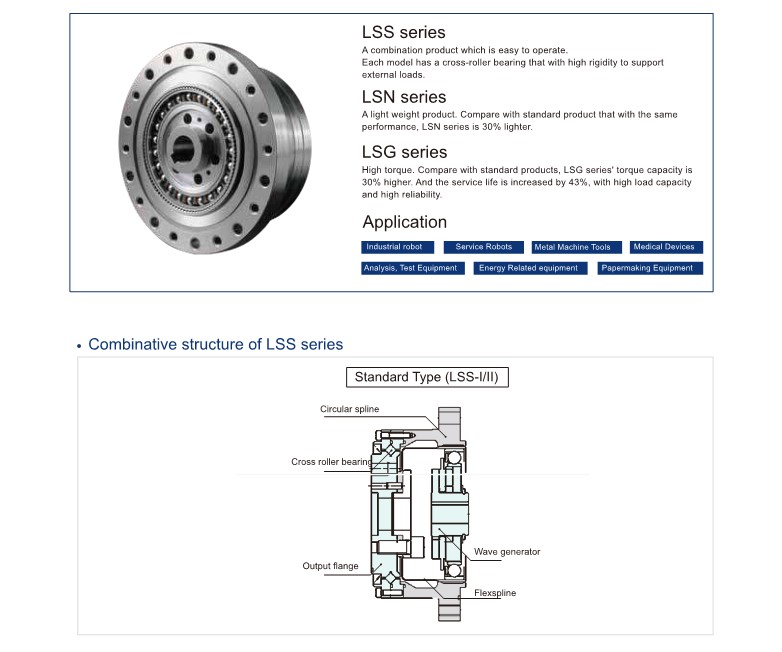

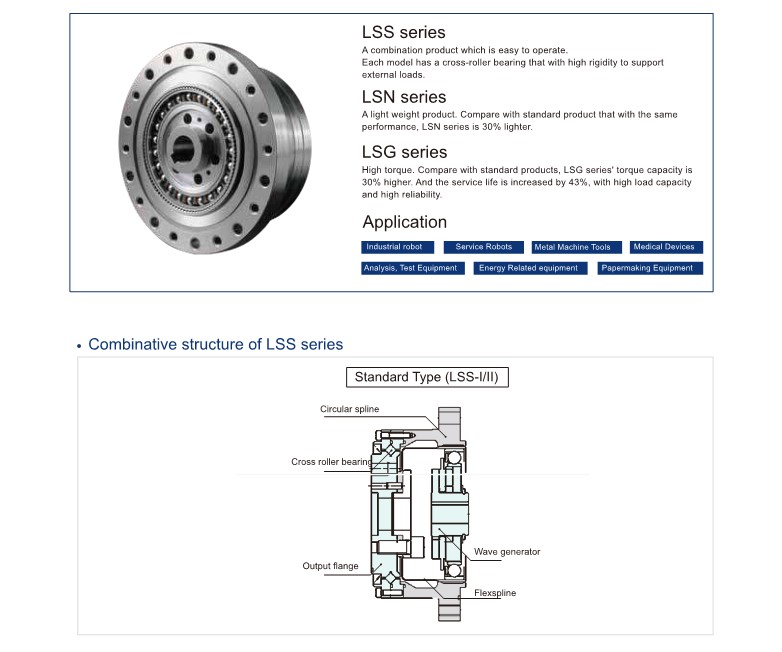

LHT Series

A combination product that with large diameter hollow hole, flat shape, which is easy to operate.

LHN Series

Light weight product, 20% lighter than standard products.

LHG Series

High torque. Compare with standard products, LHG series’ torque capacity is 30% higher. And the service life is increased by 43%,

with high load capacity and high reliablity.

LHT/LHN Rated parameters

Related Products

Company Information

EVER-POWER GROUP SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, ARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACUUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.

Certifications

FAQ

Q: Are you trading company or manufacturer ?A: Our group consists in 3 factories and 2 abroad sales corporations.Q: Do you provide samples ? is it free or extra ?A: Yes, we could offer the sample for free charge but do not pay the cost of freight.Q: How long is your delivery time ? What is your terms of payment ?A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.Q: What is the exact MOQ or price for your product ?A: As an OEM compEPG is a company specialized in the manufacture of the speed reducers for industry in general. From this idea, Mr. Alan began his activity in 1997. In small installations, the first gears and carcasses were manufactured and mechanized, while mounting the first reducers from mark EPG. With becoming to the years, we have passed from a small workshop of almost 150 meters to the new installation that occupy a surface of 5.800 meters.any, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.If you have another question, please feel free to contact us.

Product packaging

Why Choose Us

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.We have exported many products to our customers all over the world, we have long-time experience and strong technology support. Some of our customer :Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, BreviniGermany: SILOKING ,GKN ,KTSFrance: Itfran, Sedies, KuhnBrazil: AEMCO ,STUUSA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODSCanada: JAY-LOR , CANIMEX ,RingBall……-> Our Company with over twelve year’s history and 1000 workers and 20 sales.-> With over 100 Million USD sales in 2017-> With advance machinery equipments-> With large work capacity and high quality control, ISO certified…….you also can check our website to know for more details, if you need our products catalogue, please contact with us.

Contact Us

|

FOR MORE DETAIL, PLEASE CONTACT US. |

Best China manufacturer & factory Clutch Shaft Agricultural Machine Tractor Pto Drive Shaft With Ce Certificate With high quality best price

Quality and credit are the bases that make a corporation alive. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

Once the PTO has begun to power the attachment, steadily increase the throttle until you reach the operating speed. The typical running RPM (revolutions per minute) for a tractor mounted PTO is 540 RPM, although there are tractor models that rev higher. Always refer to your particular tractor model for instructions prior to first-time use.

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

Ordinary Product

- Type:

-

Shafts

- Use:

-

tractors

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate

Without adequate venting, high temperatures increase internal pressure which can force lubricant past seal lips or increase lip contact pressure, accelerating seal wear and grooving on the seal journals.

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc.

- Packaging Details

- Iron crates

- Port

- NINGBO OR SHANGHAI

Online Customization

Related product

Company Profile

Packing & Delivery

Industrial manufacturer China in Kota India Heavy Duty Plastic Roller Bearing Pulley Wheel with Steel Core for Machine with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Industrial Heavy Duty Plastic Roller Bearing Pulley Wheel with Steel Core for Machine

Products Type

We can custom shape,size,color material and quantity for plastic wheel as your requirment.

Products Specification

1. Various hardness for your choice.

2. Good abrasion, heat and oil resistance.

3. Good anti-aging performance and gas tightness.

4. Ease of bonding to EPT material.

5. EPT oxygen and ozone resistance.

6. Non-flammable,self-extinguish.

| Material | PA,PA6,PA66,PP,PE,LDPE,HDPE,UWHDPE,PTFE,POM,ABS,or Custom Compound (Any custom compound plastic is available) |

| Size | According to samples or drawings |

| Color | Black,white,red,green,transparent or any color according to Pantone colors |

| Finish | High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

| Type | Round,square,rectangular,or any nonstandard shape as request |

| Logo | Debossed,embossed,printed logo or as request |

Plastic Material Properties

Company Profile

EPT (ZheJiang ) EPT Equipment Co.,LTD is a company integrated in design,OEM&ODM plastic&rubber&CNCparts production.We can provide the be EPT products and service at a competitive price.

Main Products

We can provide EPT service,which means producing base on your drawings or samples,also we can design according to its application or customer`s requirments.

Order Operation Flow

We execute each step according to the operation process flow, strictly, seriously and meet the requirements of customers with good quality on time.

For Fa EPT Quotation,Please Inform Below Details

1. Production type

2. Material specification (or let us know the using environmental)

3. Size details? (or provide drawings or samples for refference)

4. Quantity request

5. Prefer color

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

China Lowest price manufacturer Standard high quality DIN7 M1.5 spur gear and rack for CNC machine

Every single process, every single segment, each operate in EPG is demanded to be accomplished 1 phase subsequent one more, meticulously and cautiously, from material selection, reformation to manufacturing components, from components heat treatment method to automatic assembly, from high quality management to solution inspection and screening and from purchase working to after income support.

Overview

Fast Details

- Applicable Industries:

-

Developing Substance Retailers, Production Plant, Equipment Fix Stores, Food & Beverage Manufacturing unit, farms, Vitality & Mining

- Other Place:

-

TianJin,China

- Product identify:

-

Straight Equipment Rack

- Shade:

-

Character Colour

- Application:

-

Business Equipment

- Precision grade:

-

Din7

- Area treatment method:

-

Grinding

- Hardness:

-

20-twenty five Degree HRC

- Normal:

-

common

- Stress:

-

twenty Diploma

- Sides floor:

-

Incorporated

Provide Capability

- Source Capability:

- 10000 Piece/Pieces for each Month

Packaging & Shipping

- Packaging Details

- wood/ carton

- Port

- TIANJIN PORT

-

Lead Time

: -

Quantity(Baggage) one – 2 3 – one hundred >100 Est. Time(days) three ten To be negotiated

On the internet Customization

EPG offer you widest range of gearbox and velocity reducers, conveyor chains and transmission components like equipment, sprocket, racks, pulley, shaves and taper bushes etc for various applications

Specification

|

Solution name |

Equipment rack |

||||||

|

Kind |

Helical gear rack,spur gear rack |

||||||

|

Material |

C45,steel,carbon metal,stainless metal,plastic,nylon,POM,ect |

||||||

|

Precision |

DIN6,DIN7,DIN8,DIN9,DIN10 |

||||||

|

Model |

M1,M1.twenty five,M1.five,M2.M3,M4,M5,M6,M8,M10 |

||||||

|

Approach |

Equipment Hobbing, Equipment Milling, Equipment Shaping, Gear Broaching, |

||||||

|

Warmth treatment method |

Quenching & Tempering, Carburizing & Quenching, Higher-frequency Hardening, Carbonitriding |

||||||

|

Surface area treatment method |

Blacking, Sprucing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating. |

||||||

Use to equipment

|

product title |

straight equipment rack |

|

brand |

EPG – The biggest transmission elements manufacuturer in China |

|

region of location |

TianJin,China |

|

coloration |

natural |

|

processing |

grinding |

|

Din precision |

DIN6 |

Catalog

Set up

Packing & Shipping and delivery

Primary product

Application

Firm profile

HangZhou EPG – The greatest transmission components manufacuturer in China Electrical Products Co.,Ltd was established in HangZhou in 2008 and is a specialist maker and exporter that is concerned with the design and style, advancement and creation.With thorough requirments, we can also build your particular created item. Our solution range includes all varieties of helical equipment, spur equipment, bevel equipment, equipment rack, worm gear, sprockets,chains, bearings.Maintaining in head that very good services is the important to cooperating with consumers, we strive to meet large high quality standards, offer competitive costs and guarantee prompt supply.

Payment

Parallel China Shaft Gearbox reducer for Mining gearbox for extruder machine agitator gear speed reducer with flange hoist gearbox – Supplier Manufacturer wholesaler Factory

For more data.: Cellular/Whatpp: +8613083988828

Superior thermo remedy equipment, these kinds of as network warmth treatment oven, multi-use thermo treatment oven, etc. Our goods is common exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The united states, Thailand, Pakistan, Indonesia, a lot more than 60 nations around the world and regions.

Overview

Swift Information

- Applicable Industries:

-

Building Content Stores

- Gearing Arrangement:

-

Helical

- Output Torque:

-

470000Nm

- Input Speed:

-

750-1500rpm

- Output Velocity:

-

1.7~1200rpm

- Location of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Certification:

-

ISO9001-2008

- Bearing:

-

LYC

- Gear Precision Quality:

-

Din 4

- Sample:

-

Available

Supply Ability

- Source Ability:

- 500 Unit/Models per Month

Packaging & Supply

- Packaging Particulars

- Normal wooden situation or as asked for

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Quantity(Boxes) one – one >1 Est. Time(times) 60 To be negotiated

Online Customization

Item Description

Parallel Shaft Gearbox gearbox for Mining gearbox for extruder equipment agitator equipment pace gearbox with flange hoist gearbox

Gain:

SLH series high electricity velocity gearbox has the attributes of high flexibility,very good mixture and heavy loading ability, together with other merits this kind of as simple to attain a variety of transmission ratios, higher performance, low vibration and higher permissible axis radial load.

Requirements:

1) Output speed: one.7~1200r/min

two) Output torque: up to forty seven,000N.m

3) Motor power: two.52~5366kW

4) Mounted type: foot-mounted ,flange-mounted, axis mounted, shrink mounted

Items Demonstrate

Packing

FAQ

Q1: What details need to I explain to you to validate the solution?

A: Model/Size, Transmission Ratio, Shaft instructions & Get amount.

Q2: What can i do if I do not know which a single I require?

A: Do not be concerned, Send as a lot data as you can, our group will aid you locate the appropriate one you are hunting for.

Q3:What is your solution warrenty period of time?

A:We offer a single 12 months warrenty considering that the vessel departure date remaining China.

This fall: What is your terms of payment ?

A: thirty% T/T in progress ,equilibrium ahead of shippment.

If you have another query, pls truly feel totally free to make contact with me.

Speak to US

EPG – one particular of the most significant transmission factory in China, major items: worm geared motors, agricultrual gearbox, planetary gear generate, helical,screw, beve gears and spare components and agricultural components manunfacuter in ChinaFor far more information.: Cell/Whatpp: +8613083988828